Chapter 5 Function parameter

49

Ch

ap

ter 5

382.

E1.50

Simple PLC run-time unit

0: S (seconds) 1: H (hours)

0

☆

383.

E1.51

Multi-stage command 0

reference manner

0: Function code E1.00 reference

1: Analog AI1 reference

2: Analog AI2 reference

3: Panel potentiometer setting

4: High-speed pulse setting

5: PID control setting

6:Keyboard set frequency (F0.01)

setting, UP/DOWN can be

modified

7. Analog AI3 given

0

☆

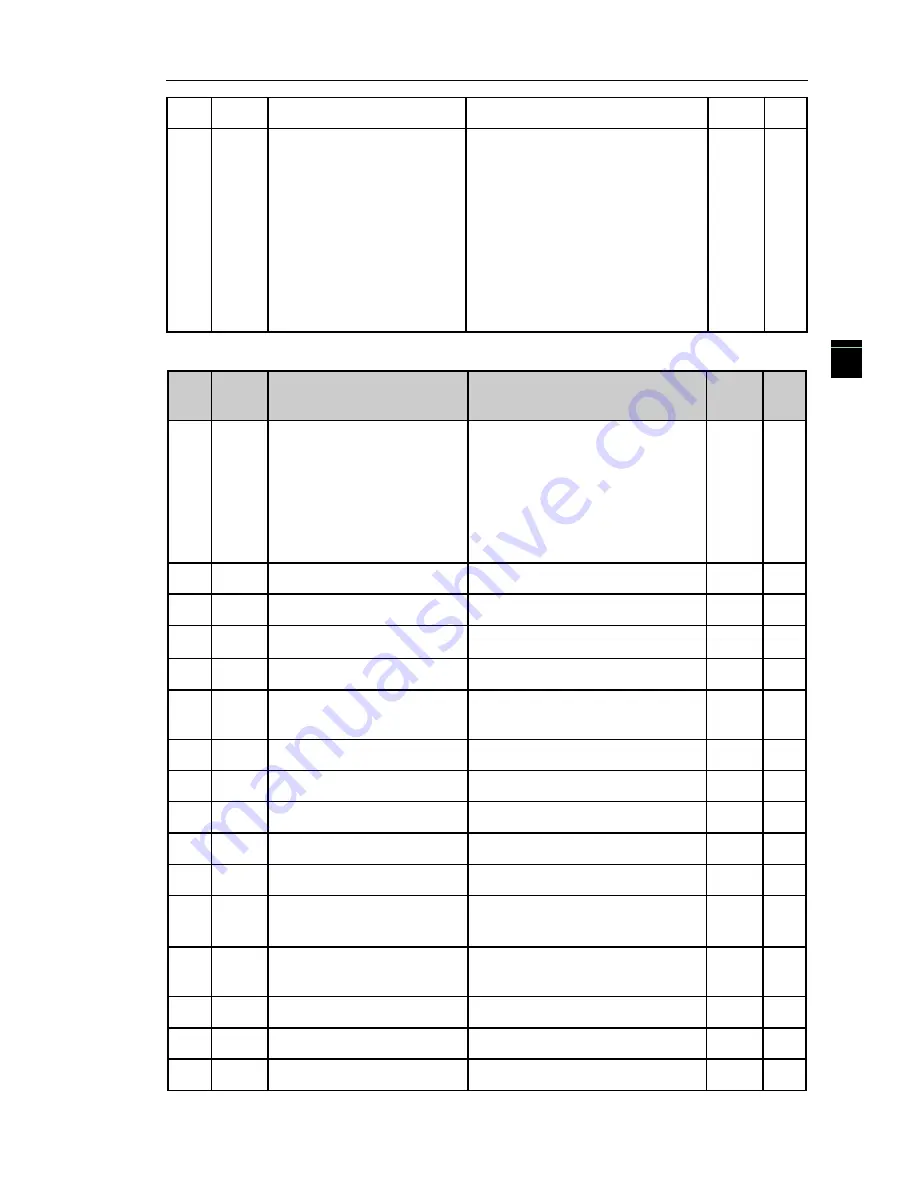

5-1-17.

E2 Group - PID function

No.

Code

Parameter name

Setting range

Factory

setting

Chan

ge

384. E2.00 PID setting source

0: E2.01 setting

1: Analog AI1 reference

2: Analog AI2 reference

3: Panel potentiometer setting

4: High-speed pulse setting

5: Communications reference

6: Multi-stage command reference

0

☆

385. E2.01 PID keyboard reference

0.0% to 100.0%

50.0%

☆

386. E2.02 PID feedback source

0 to 8

0

☆

387. E2.03 PID action direction

0: positive 1: negative

0

☆

388. E2.04 PID setting feedback range

0 to 65535

1000

☆

389. E2.05

PID inversion cutoff

frequency

0.00 to F0.19(maximum

frequency)

0.00Hz

☆

390. E2.06 PID deviation limit

0.0% to 100.0%

0%

☆

391. E2.07 PID differential limiting

0.00% to 100.00%

0.10%

☆

392. E2.08 PID reference change time

0.00s to 650.00s

0.00s

☆

393. E2.09 PID feedback filter time

0.00s to 60.00s

0.00s

☆

394. E2.10 PID output filter time

0.00s to 60.00s

0.00s

☆

395.

E2.11

PID feedback loss detection

value

0.0%: not judged feedback loss

0.1% to 100.0%

0.0%

☆

396. E2.12

PID feedback loss detection

time

0.0s to 20.0s

0.0s

☆

397. E2.13 Proportional gain KP1

0.0 to 200.0

80.0

☆

398. E2.14 Integration time Ti1

0.01s to 10.00s

0.50s

☆

399. E2.15 Differential time Td1

0.00s to 10.000s

0.000s

☆