4

5

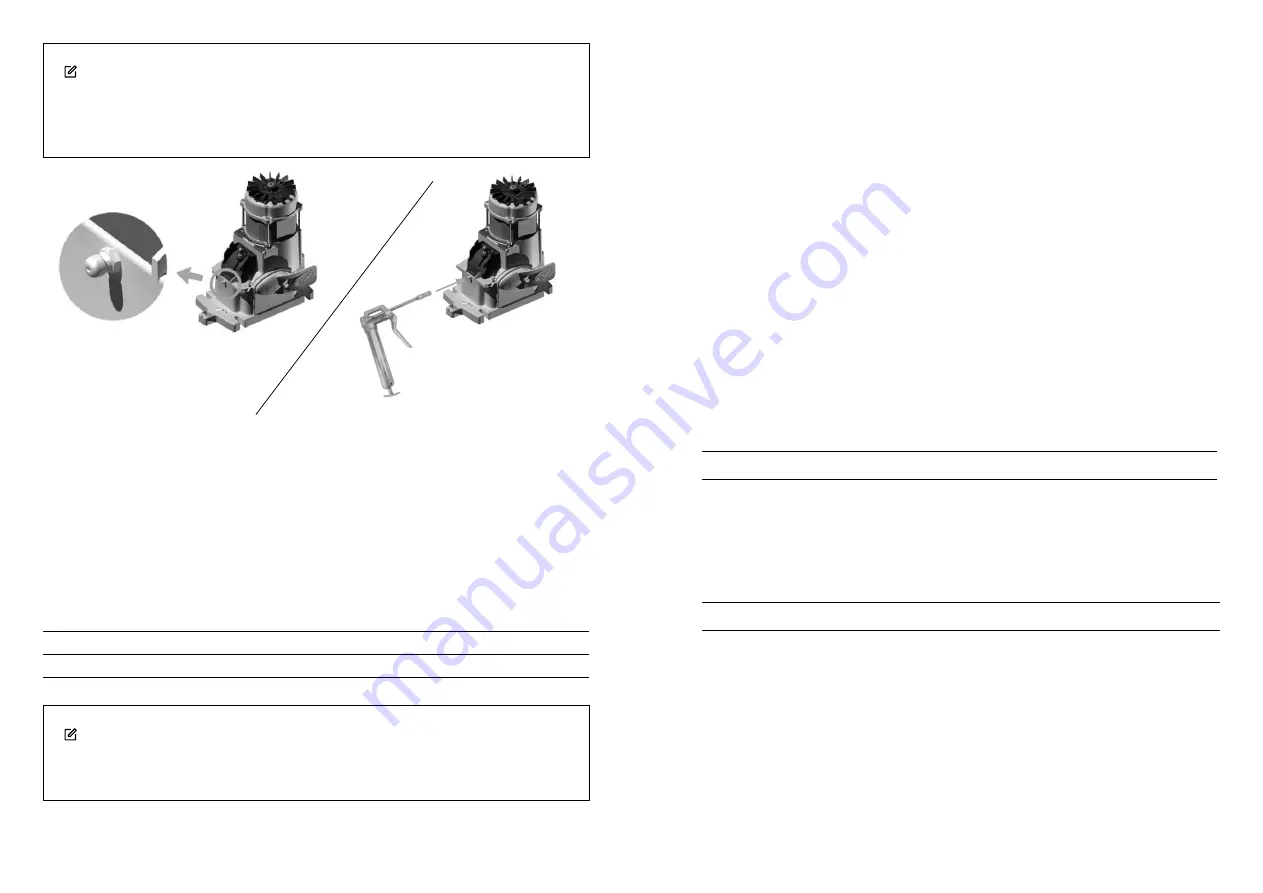

NOTE:

This product is manufactured with the 'M6' straight grease fitting

that makes it easy to grease the internal crown, as the gearmotor does

not need to be disassembled for maintenance to be carried out, providing

installers with quickness and convenience.

Site preparation:

1.

Pass a 3/4” pipe through the concrete floor/plinth from the center of the

plinth to the circuit breaker panel at the site, from where the equipment's

electrical supply will come out.

2. Provide the routing of the power cables and pushbuttons through this

piping to the place where the equipment will be operated. Refer to the

table below for choosing the proper cable, according to the NBR 5410

standard (in Brazil).

Motor power supply

Cable type and gauge

110V

One 2-way x 2.50²mm AWG cable

220V

One 2-way x 2.50²mm AWG cable

NOTE:

If accessories are used, provide the pipes and cables as needed.

Provide a grounding rod that will be fixed close to the automatic barrier

cubicle.

GENERAL FEATURES

•

'Universal' cubicle - the beam can be installed on either side of the cubicle

•

Release system for manual unlocking (up to 4.5m - 14.8 ft)

• Electronic control board with a variable frequency drive

•

Mechanical stopper with height adjustment

•

System actuation through a gearmotor, pinion and chains

•

Galvanized steel cubicle with anticorrosive treatment and electrostatic

painting that ensure great resistance against weather conditions

•

Limit switch system with encoder

• Electronic brake

•

It allows the installation of several accessories (inductive loop, visual exit

annunciator, photocell, pushbutton etc.).

TECHNICAL SPECIFICATIONS

‘Barrier BRC’ Automatic barrier (Straight beam)

Beam length

Cycles / hour

(Adjustable)

Opening

speed

(Adjustable)

closing

speed

Absorbed

power

Input Voltage

2.5 to 3.5m

(~8.3 to 11.5 ft)

450

2 sec.

2.5 sec.

1 HP

127 / 220V

Barrera Barrier BRC (Brazo / Mástil articulable)

Beam length

Cycles / hour

(Adjustable)

Opening

speed

(Adjustable)

closing

speed

Absorbed

power

Input Voltage

2.5 to 3.5m

(~8.3 to 11.5 ft)

300

2 sec.

2.5 sec.

1 HP

127 / 220V