12

13

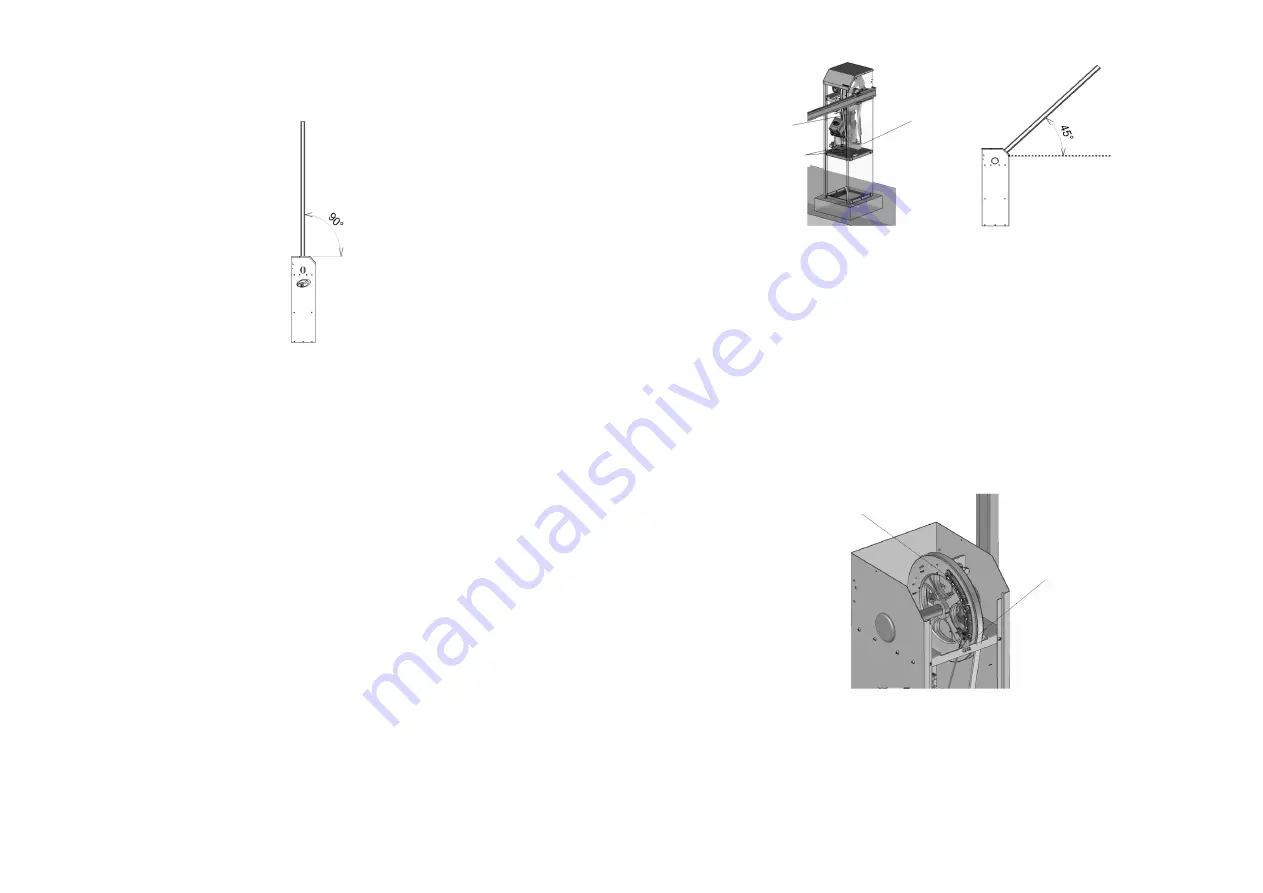

13. The automatic barrier will be in good opening condition, when the

beam / boom is in the condition shown in the image below.

Note:

It is not necessary to balance the beam again, as it leaves the

factory balanced. However, if necessary, follow the instructions below.

BALANCING THE BEAM AND CHECKING THE

CHAIN

1. Remove the gearmotor from the cubicle, leaving the chain free.

Check if the beam remains at a position around 45°. Otherwise, the

adjustment will be made through the spring bolt, either loosening or

tightening it until the ideal adjustment is reached.

2. Once this is done, place the gearmotor and the chain again. Check

if it is properly stretched and ready for operation. With your thumb,

apply an even pressure on the chain. If it does not bend, it is properly

stretched. If the chain is loose, adjust it using the belt tensioning

bolts, using a wrench according to the respective nut.

ADJUSTING THE MAGNET BARS

With the beam properly balanced, and with its opening and closing

'mechanical stoppers' adjusted, check if it is necessary to adjust the

magnet bars.

1. Keep the beam in the 'open' position (90°).

2.

Adjust the magnet bar so that the last magnet is in front of the Sensor

Hall (Encoder) and tighten the fixing bolts.

Note:

Perform the same procedure with the beam in the 'closed' position

(0°).

The automatic barrier is ready to operate. Turn on the circuit breaker,

press the '+' button on the electronic control board and the barrier will

function.

Chain

Spring Bolt

Magnet Bar

Hall Sensor

Chain

Stretchers