29

24.6 - Open end-of-stroke indication

'FC' LED blinks when the gate is on an open end-of-stroke area.

24.7 - Close end-of-stroke indication

'FC' LED keeps lit when the gate is on a closed end-of-stroke area.

24.8 - Capacitor load indication

'BUS' LED indicates that the high voltages capacitors are charged. Do not touch them while this LED is ON (even when the control board

is disconnected from the power supply.

24.9 – Encoder Test

It is possible to test the operator's encoder; to do so; simply connect it to the control board and check if the 'ENCA' and 'ENCB' are

blinking when the operator runs. Each LED corresponds to a specific sensor; for example, 'ENCA' LED corresponds to the 'A' sensor inside

the gear motor.

24.10 - Thermal Protection

The operator has a thermal protection device that shuts off the motor when it reaches a temperature above 310 ºF.

The control board receiving two consecutive commands during this period, it will enter in hardshutdown mode (Audio alarm will

sound) and the operator will need to be reset.

For more information see topic 13.5.

25 - MAINTENANCE

On the table below, are cited some PROBLEMS - FAULTS, POSSIBLE CAUSES AND CORRECTION - which may occur in your operator.

Before any maintenance, the total disconnection from the mains is required.

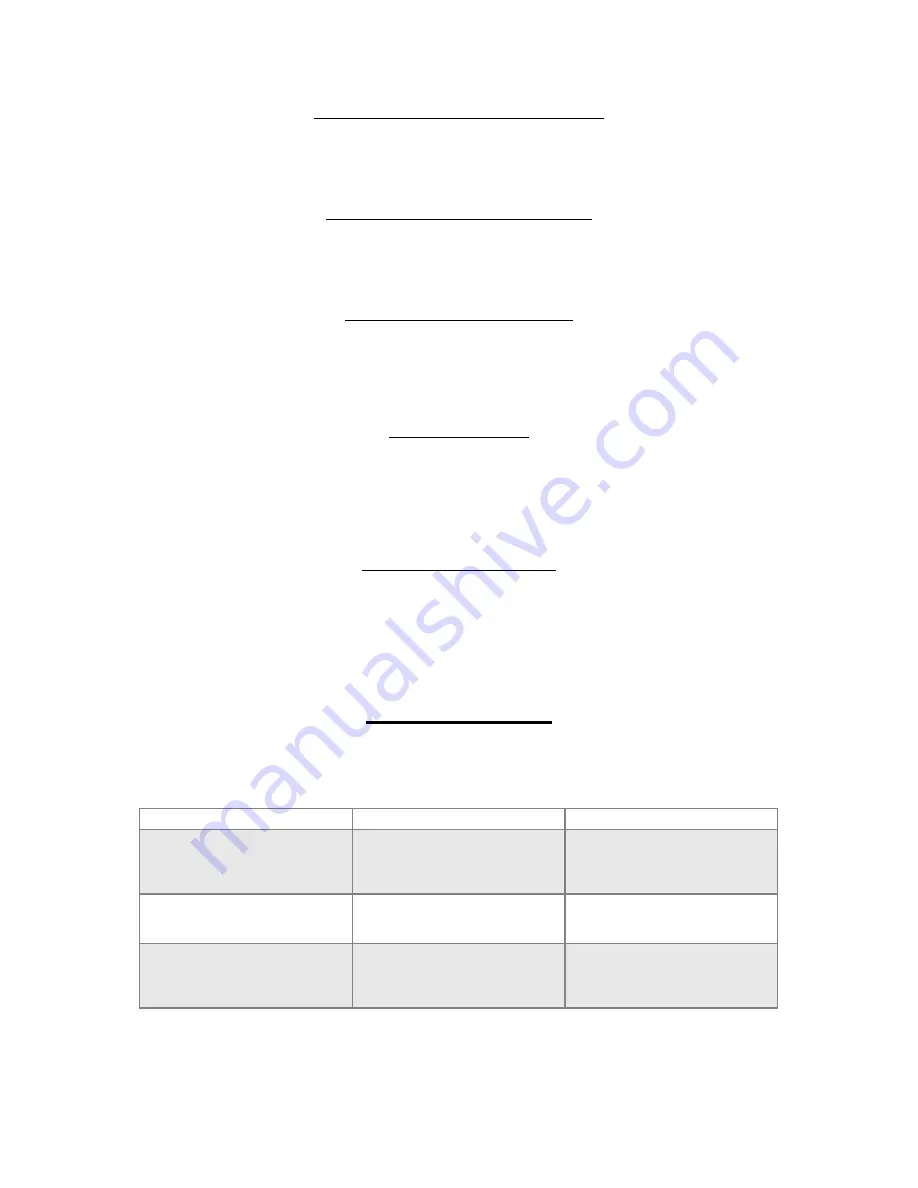

TROUBLES / SOLUTIONS

FAIL

CAUSE

SOLUTION

The gate does not correspond to the

path of the place where the operator

has been installed (It breaks before it

reaches the stop or slams when closing).

There is an acquired path different from

the place where the operator has been

installed.

Press both '+' and '-' buttons at the

same time and keep them pressed until

'OSC' LED lits.

Gate keeps open and whenever it

receives opening commands, it closes.

Acquiring was not properly performed.

Refer to item 'First operation after a

frequency inverter is installed on the

operator (Acquiring).

'OSC' LED blinks rapidly and the motor

turns itself off.

Current sensor activated. This may

happen when the motor has a

malfunction.

Check stator resistance. Check the

motor current (It must be less than

medium 3A RMS and 5A RMS peak

current (2s maximum)).

Summary of Contents for DZ 1500

Page 1: ...DZ PREDIAL DZ CONDOMINIUM DZ 1500 Technical Manual...

Page 2: ......

Page 30: ...30 26 REPAIR PARTS DZ PREDIAL JET FLEX 60HZ U...

Page 31: ...31...

Page 32: ...32 DZ CONDOMINIUM JET FLEX 60HZ U...

Page 33: ...33...

Page 34: ...34 DZ 1500 JET FLEX 60HZ Z12 U...

Page 35: ...35...