13

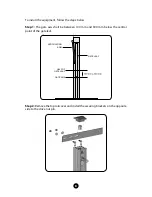

COMMAND BOARD:

Check the label attached to the

product (according to the model

on the side) which is the command

board part of the operator. Once this

is done, consult the board manual

that is available for download at www.

ppa.com.br and make all connections

and configurations.

illustr

ativ

e images

Code:

Model:

Reduction:

Technology:

Voltage:

Board:

Size:

Assembly:

Fairing:

Gear:

MAINTENANCE

In the table below, we will mention some PROBLEMS - DEFECTS, PROBABLE CAUSES

AND CORRECTIONS - which may occur in your operator. Before any maintenance, it

is necessary to completely disconnect the electricity.

DEFECTS

PROBABLE CAUSES

CORRECTIONS

Engine does not

start / does not

move

A) Power off

B) Open / burned fuse

C) Locked gate

D) Defective limit switch

A) Make sure that the power supply

is connected correctly

B) Replace fuse with the same

specification

C) Make sure that there is no object

blocking the operation of the gate

D) Replace the limit switch system

(analog and / or digital)

Motor blocked

A) Inverted motor connection

B) Blocked gate or trigger

A) Check the motor wires

B) Set to manual mode and check

separately

Command board

does not accept

command

A) Fuse blown

B) Power line off (power)

C) Defect on remote control

unloaded

D) Transmitter range (remote

control)

A) Replace the fuse

B) Connect the power supply

C) Check and replace battery

D) Check the position of the

receiver's antenna and, if necessary,

reposition it to ensure the reach

Motor only turns

to one side

A) Inverted motor wires

B) Inverted end-of-course system

C) Defect in the command center

A) Check the motor connection

B) Invert the limit switch connector

(analog and / or digital)

C) Replace the board