8

User Manual

SCANEX PLUS

Table 3.4

Parameter Description

Settings

(Default Value)

OPERATOR PAGE & PARAMETERS

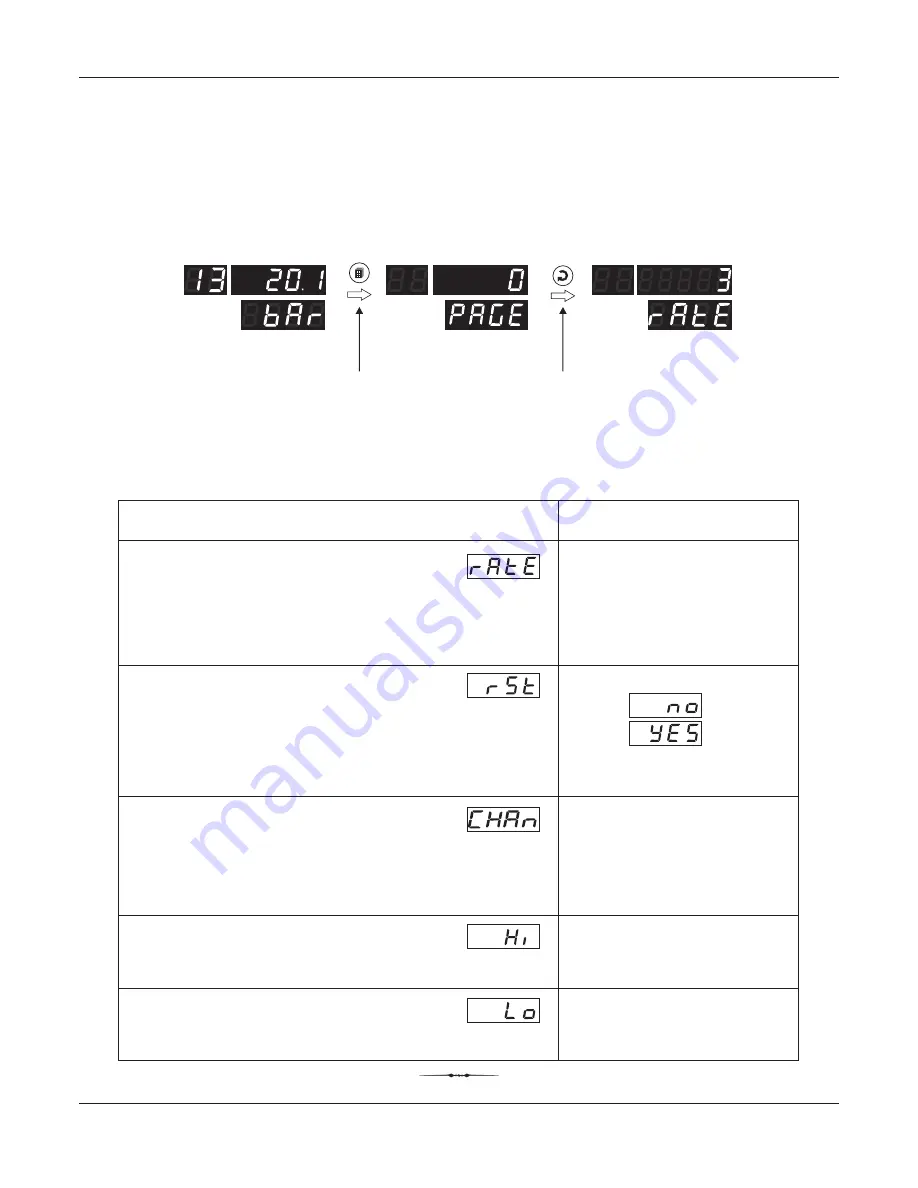

The Operator page contains the parameters that are used most frequently and the commands that are required for day-to-day

operation. This page is not locked for editing by Master Lock. The Figure 3.2 below illustrates how to access Operator Page

(Page 0).

RESET COMMAND

This feature clears the current Min/Max values of all Channels and

starts afresh monitoring the channels for new highest and lowest

values.

For resetting, set the reset command to ‘Yes’.

View Only

(Default : NA)

MINIMUM PV

The minimum PV attained by the selected channel.

View Only

(Default : NA)

MAXIMUM PV

The maximum PV attained by the selected channel.

No

Yes

(Default : No)

1 to Actual no. of

Channels to Scan

(Default : 1)

CHANNEL NUMBER

Select the channel No. whose Min/Max PV is to be viewed.

This Parameter reappears cyclically after viewing Max/Min Values

for each selected channel number.

1 Sec. to 99 Sec.

(Default : 3 Sec.)

SCAN RATE

Applicable for Auto Scan Mode only. This parameter value sets the

time interval for which each channel is displayed. In other words,

the rate at which the channels are sequentially updated for

indication.

The Operator Page parameters are listed in Table 3.4 below.

Figure 3.2

Operator Page

First Parameter

on Operator

Page

Press PAGE

key to enter

Set-up mode

Press ENTER

key to open

Operator Page

MAIN

Display

Mode