23

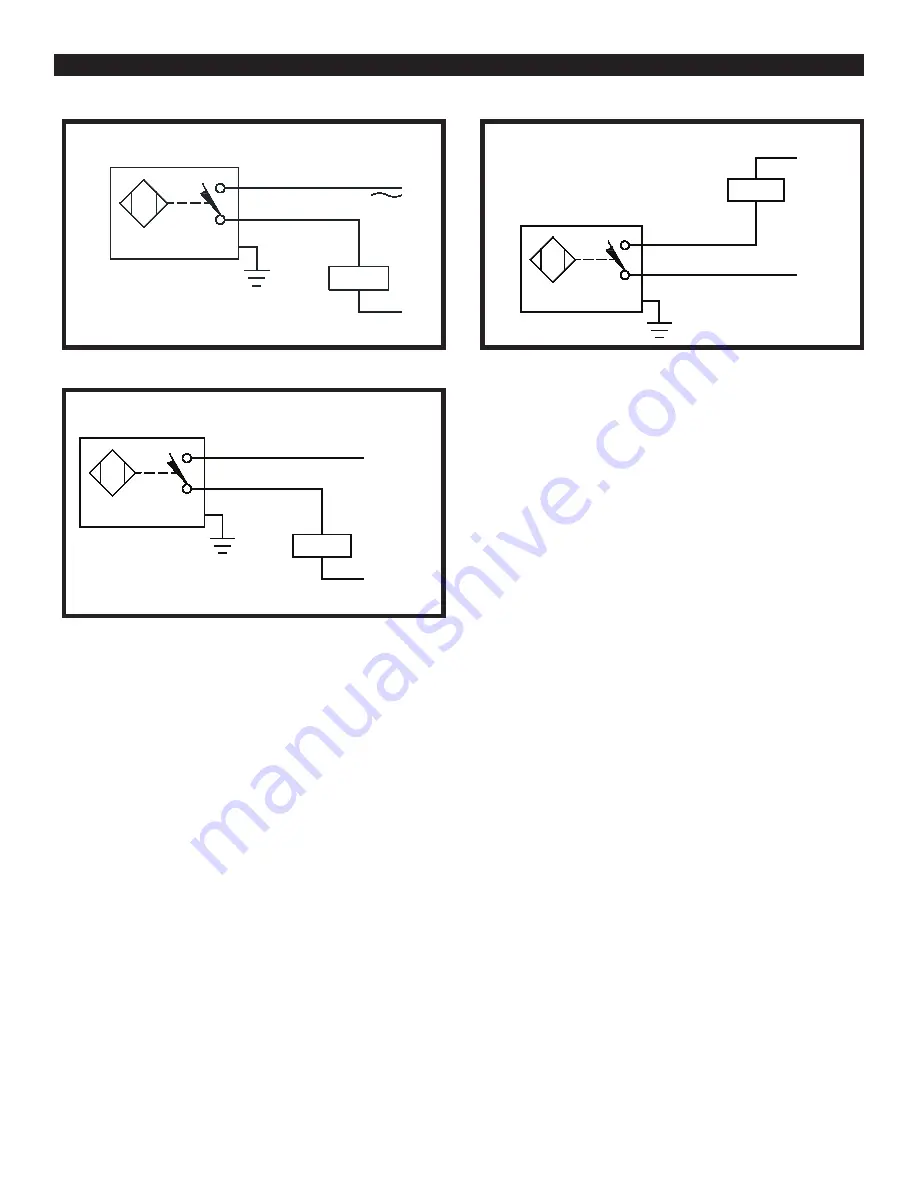

Figures A4 .1, A4 .2, and A4 .3 show Smart Roll Sensor wiring diagrams . For these diagrams, the Smart Monitor or PLC provides the load .

SENSOR SPECIFICATION:

• 2 wire AC/DC inductive sensor

• 20–250 VAC, 10 –300 VDC

• Short Circuit and Overload Protection

• Normally Open

• 2 meter cable, PVC jacket; 22 AWG copper conductors, PVC insulated .

Line Frequency: 50-60 Hz

Differential Travel (Hysteresis): 3-15% (5% typical)

Voltage Drop Across Conducting Sensor: <=6 .0V at 100 mA

Continuous Load Current: <= 100 mA

Trigger Current for Overload Protection: >= 220 mA

Off State (Leakage) Current: <= 1 .7 mA

Minimum Load Current: >= 3 .0 mA

Inrush Current: <=1 .0A (<=30ms, 15% Duty Cycle)

Time Delay Before Availability: <=60 ms

Power-On Effect: Per IEC 947-5-2

Transient Protection: Per EN 60947-5-2

Operating Temperature: -25°C to +70°C (-13° F to 158°F)

Repeatability: <=2% of Rated Operating Distance

Temperature Drift: ±10%

A4. SMART ROLL SENSOR WIRING DIAGRAMS AND SPECIFICATIONS

BU

BN

LOAD

(YL/GN)

2 Wire DC Sinking (NPN)

Circuit Wiring Diagram

+V

-V

BU

BN

L1

L2

LOAD

(YL/GN)

FIGURE A4 .1: 2 WIRE AC CIRCUIT WIRING DIAGRAM

FIGURE A4 .2: 2 WIRE DC SINKING (NPN)

CIRCUIT WIRING DIAGRAM

BU

BN

LOAD

(YL/GN)

2 Wire DC Sourcing (PNP)

Circuit Wiring Diagram

+V

-V

FIGURE A4 .3: 2 WIRE DC SOURCING

(PNP) CIRCUIT WIRING DIAGRAM