9116 - Product Version 9116-003

45

9116QB01

LERBAKKEN 10, 8410 ROENDE DENMARK

Revision date:

2013-05-31

Version Revision

V6 R0

Prepared by:

PB

Page:

2/4

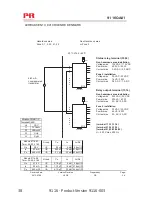

Terminal 51-52, 51-53

Terminal 51-52, 51-53

Ui

30 V

Ui

30 V

Ii

120 mA

Ii

120 mA

Pi

900 mW

Pi

900 mW

Ci

3 nF

Ci

3 nF

Li

1

μ

H

Li

1

μ

H

Uo

28 V

IIC

80 nF

4 mH 54

μ

H/

Ω

Uo

21.4 V

IIC

0.16

μ

F

4 mH 54

μ

H/

Ω

Io

93 mA

IIB

640 nF

16 mH 218

μ

H/

Ω

Io

93 mA

IIB

1.13

μ

F

16 mH 218

μ

H/

Ω

Po

650 mW

IIA

2.1

μ

F

32 mH 436

μ

H/

Ω

Po

650 mW

IIA

4.15

μ

F

32 mH 436

μ

H/

Ω

Uo

28 V

IIC

80 nF 1000 mH 4 mH/

Ω

Uo

21.4 V

IIC

0.16

μ

F 1000 mH 4 mH/

Ω

Io

1.1 mA

IIB

640 nF 1000 mH 17 mH/

Ω

Io

1.1 mA

IIB

1.13

μ

F 1000 mH 17 mH/

Ω

Po

8 mW

IIA

2.1

μ

F 1000 mH 35 mH/

Ω

Po

8 mW

IIA

4.15

μ

F 1000 mH 35 mH/

Ω

Uo

8.3 V

IIC

7

μ

F 1000 mH 100 mH/

Ω

Uo

8.3 V

IIC

7

μ

F 1000 mH 100 mH/

Ω

Io

0.2 mA

IIB

73

μ

F 1000 mH 400 mH/

Ω

Io

0.2 mA

IIB

73

μ

F 1000 mH 400 mH/

Ω

Po

0.4 mW

IIA

1000

μ

F 1000 mH 800 mH/

Ω

Po

0.4 mW

IIA

1000

μ

F 1000 mH 800 mH/

Ω

Uo

8.3 V

IIC

7

μ

F

207 mH

1 mH/

Ω

Uo

8.3 V

IIC

7

μ

F

207 mH

1 mH/

Ω

Io

13.1 mA

IIB

73

μ

F

828 mH

5 mH/

Ω

Io

13.1 mA

IIB

73

μ

F

828 mH

5 mH/

Ω

Po

27.3 mW

IIA

1000

μ

F 1000 mH 10 mH/

Ω

Po

27.3 mW

IIA

1000

μ

F 1000 mH 10 mH/

Ω

Module 9116B2

Terminal 51-54, 52-54

Group

Module 9116B2

Terminal 51-53

Co

Group

Lo

Lo/Ro

Co

Lo

Lo/Ro

Lo/Ro

Lo

Module 9116B1

Terminal 41,42,43,44

Module 9116B1

Terminal 51-52

Group

Group

Module 9116B2

Terminal 41,42,43,44

Group

Lo/Ro

Lo/Ro

Module 9116B2

Terminal 51-52

Group

Group

Co

Lo

Lo/Ro

Co

Co

Lo

Lo/Ro

Co

Lo

Module 9116B1

Module 9116B2

Module 9116B1

Terminal 51-54, 52-54

Group

Module 9116B1

Terminal 51-53

Co

Lo

Lo/Ro

Co

Lo

Notas de instalação:

Instalação em grau de poluição 2, categoria de sobretensão II conforme definido no IEC 60664-1

Não separe conectores quando energizado ou quando uma mistura de gás explosivo estiver

presente.

Não monte ou remova módulos do trilho de alimentação quando uma mistura explosiva de gás

estiver presente.

Desligue a alimentação antes da manutenção.

A fiação de terminais sem uso não é permitida.

A fonte de Loop e terminais de entrada de corrente para o mesmo canal não deve ser aplicada ao

mesmo tempo.

Em tipo de proteção [Ex ia Da] os parâmetros para a segurança intrínseca para grupo de gás IIB

são aplicáveis.

Para a instalação em Zona 2, o módulo deve ser instalado em um invólucro certificado conforme

as normas da série ABNT NBR IEC 60079 que proporcione um grau de proteção de pelo menos

IP54. Dispositivos de entrada de cabo e elementos de vedação devem cumprir com os mesmos

requisitos.

Para a instalação de trilho de energia na Zona 2, apenas o trilho de alimentação Rail 9400

fornecido pela Unidade de Controle de Potência 9410 é permitido.