Pratt & Whitney Rzeszów S.A.

MAINTENANCE MANUAL

PZL-10W ENGINE

2008.01.20

79-02-00

Page 401

Export Control Classification: PL/UE 9E999

OIL SYSTEM - REMOVAL AND INSTALLATION

1.

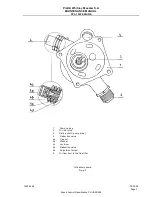

Oil delivery pump replacement (see Dwg. 401).

NOTE:

During removal and installation of pipes follow the recommendations of Section 70-02-00

REMOVAL / INSTALLATION Para 1.

A.

Oil delivery pump removal.

(1)

Drain the oil from the oil tank (see Helicopter Service Manual).

(2)

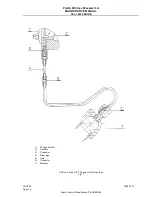

Unsecure and unscrew the nut (1) of the oil supply tube from the oil tank to the oil pump stub (2).

(3)

Disconnect the tube from the oil pump.

(4)

Unscrew the nuts (3) attaching the pump to the accessory gearbox casing and remove the

washers (4).

(5)

Remove the oil pump (5) and washer (6) from the bolts (10).

(6)

Remove the seal ring (9) from the pump casing and if it is not damaged, place it on the new pump.

(7)

Put the handling plugs from the new pump on the stub (2) and oil flow duct (7)or wrap the stub flange

with polyethylene foil.

B. Oil delivery pump Installation.

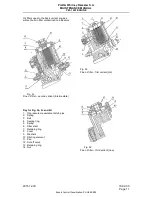

NOTE: Carry out the installation of the oil pump on the case of drive gearbox taking into account

requirements: see 72-02-00 MAINTENANCE PRACTICES clause 3. E.

(1)

Remove the handling plugs.

(2)

Drain the oil from the pump internal spaces.

(3)

Inspect the pump for damage, scores or dents.

(4)

Wipe the pump and accessory gearbox flanges with cloth moistened with gasoline (see 72-02-00 Table

202, item 4).

(5)

Check the seal ring (8) on the accessory gearbox casing sleeve and seal ring (9) on the pump casing.

Seal ring damage is not allowed.

CAUTION:

REPLACE DAMAGED SEAL RING (8) (SEE 72-02-00, TABLE 203, ITEM 21) AND /

OR SEAL RING (9) (SEE 72-02-00, TABLE 203, ITEM 25) WITH NEW ONE.

(6)

Prepare the adhering surface of case of drive gearbox, washer (6) and pump (5) in order to connect

these units.

Next put the leak stopper (see 72-02-00. Table 202. item 45) on both sides of the washer (6) - (see 72-

02-00 Table 203 item 26).