Functional characteristics

MIG/MAG welding

Item No.: 099-004838-PRA01

39

5.2.6

Special parameter, “DRIVE 4 P wire feed units”

The special parameters cannot be viewed directly since they are normally only set and stored once. The

machine control offers the following special functions:

5.2.6.1

Special parameters list

Function

Setting options

Ex works

P1

Ramp time for wire creep

0 = normal creep

(10 sec ramp time)

1 = quick creep

(3 sec ramp time)

0

P2

Program "0", releasing the

program block

0 = blocking of P0

1 = no blocking of P0

0

P3

Display mode torch power control 0 = normal display

1= flashing display

0

P4

Program restriction

Programs 2 to max. 15

15

P5

Special cycle in the special

latched and non-latched

operating modes

0 = normal (previous) non-latched/latched

1 = DV3 cycle for non-latched/latched

0

P6

Enable special JOBs SP1 to SP3

(M3.70 only)

0 = no enabling

1 = enabling of Sp1-3

0

P7

Correction mode, limit value

setting

0 = correction mode switched off

1 = correction mode switched on

The control indicates that the correction

operation is switched on by flashing the "main

program (PA)" LED

0

P8

Program changeover with

standard torch

0 = normal (previous) latched

1 = P8 function on (special latched)

0

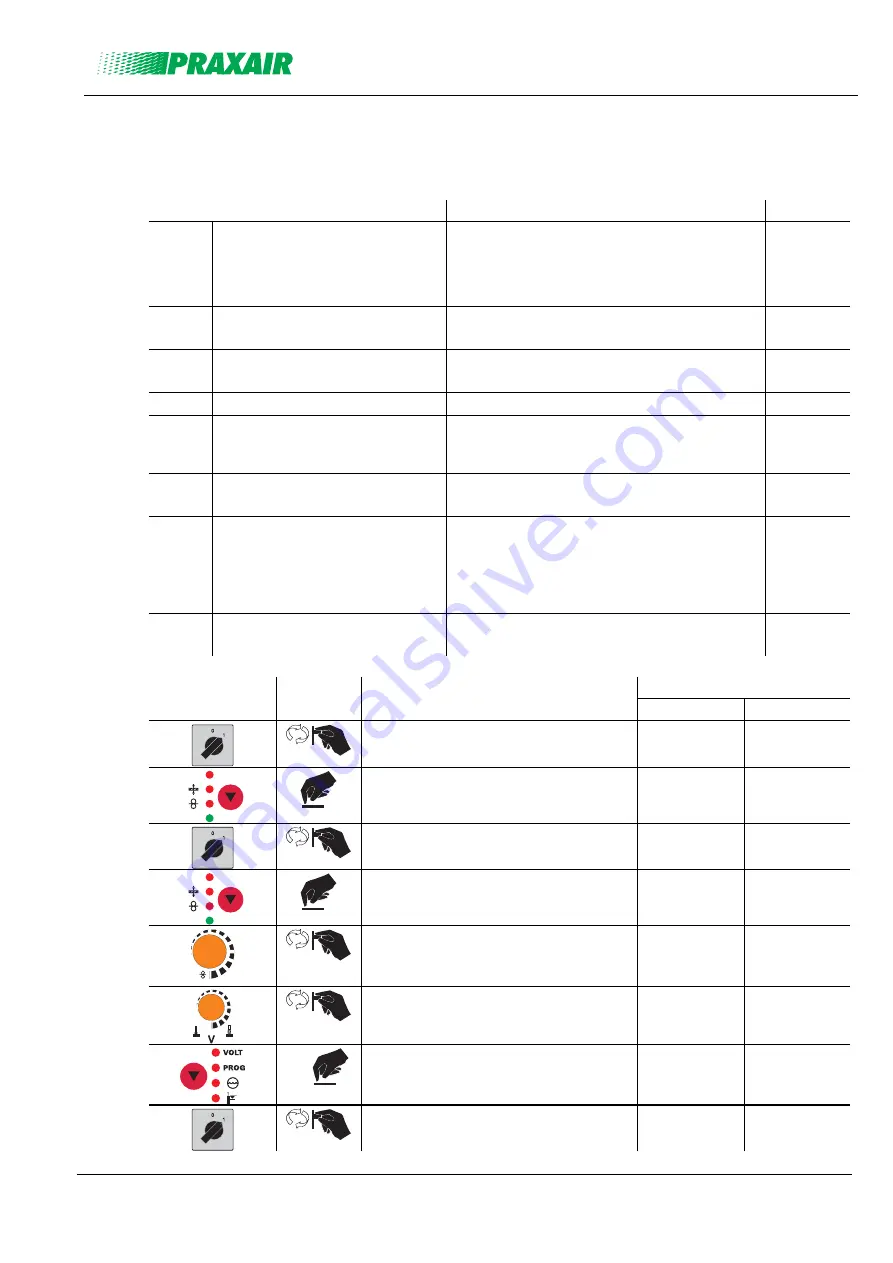

5.2.6.2

Selecting, changing and saving parameters

Display

Operating

Element

Action Result

Left Right

Switch off the welding machine

-

-

HOLD

AMP

Keep the key button pressed

-

-

Switch on the welding machine

-

-

HOLD

AMP

Release the key button

P 1

Value

m/min

Parameter selection

(see list of special parameters)

P 1-7

Value

Parameter setting

(see list of special parameters)

P x

Value

1 x

Saving the special parameters

PHO

370

Switch of the welding unit and restart in

order to put the modifications into effect

- -