Functional characteristics

MIG/MAG welding

36

Item No.: 099-004838-PRA01

5.2.3.9

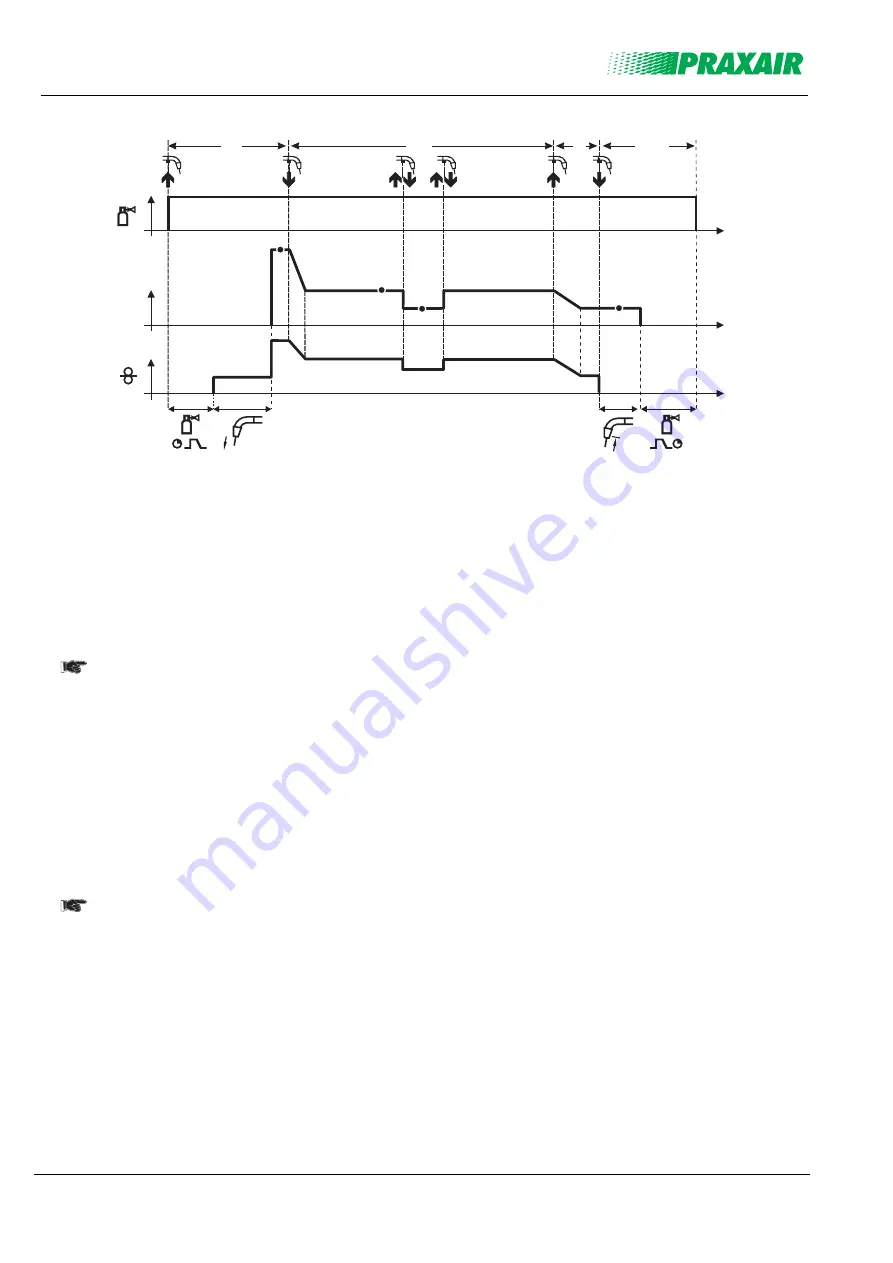

Latched special

t

t

t

I

1.

2.

3.

4.

P

A

P

B

P

END

P

START

Figure 5-12

Step 1

• Press and hold torch trigger

• Shielding gas is expelled (gas pre-flows)

• Wire feed motor runs at “creep speed”.

• Arc

ignites

after the wire electrode makes contact with the workpiece, welding current is flowing (start

program P

START

)

Step 2

• Release torch trigger

• Slope to main program P

A

.

The slope on main program P

A

is given at the earliest after the set time t

START

elapses and at

the latest when the torch trigger is released.

Tapping

1)

can be used to change over to the reduced main program P

B

.

Repeated tapping will switch back to the main program P

A

.

Step 3

• Press and hold torch trigger

• Slope to end program P

END

.

Step 4

• Release torch trigger

• WF motor stops.

• Arc is extinguished after the preselected wire burn-back time expires.

• Gas post-flow time elapses.

1)

Prevent tapping (brief press and release within 0.3 seconds)

If the welding current is to be prevented from switching over to the reduced main program

P

B

by tapping, the parameter value for WF3 needs to be set to 100% (P

A

= P

B

) in the program

sequence.