Faults

25

Faults

WARNING

Operation of a damaged or malfunctioning compressor can lead to serious or even

fatal injuries.

In the event of a fault, disconnect the compressor from the power supply immedi-

ately.

In the event of a fault, vent the compressor manually immediately.

Use the compressor only when the fault has been rectified.

ATTENTION!

The compressor is at risk of damage if repairs are carried out by unauthorised persons.

Make sure repairs to the compressor are only carried out by the manufacturer.

Faults

If faults occur on the compressor that you are unable to rectify through lubrication and cleaning, you must

notify PREBENA Service.

Do not attempt to perform any repair work on the compressor yourself.

Make sure all faults on the compressor are rectified by PREBENA Service.

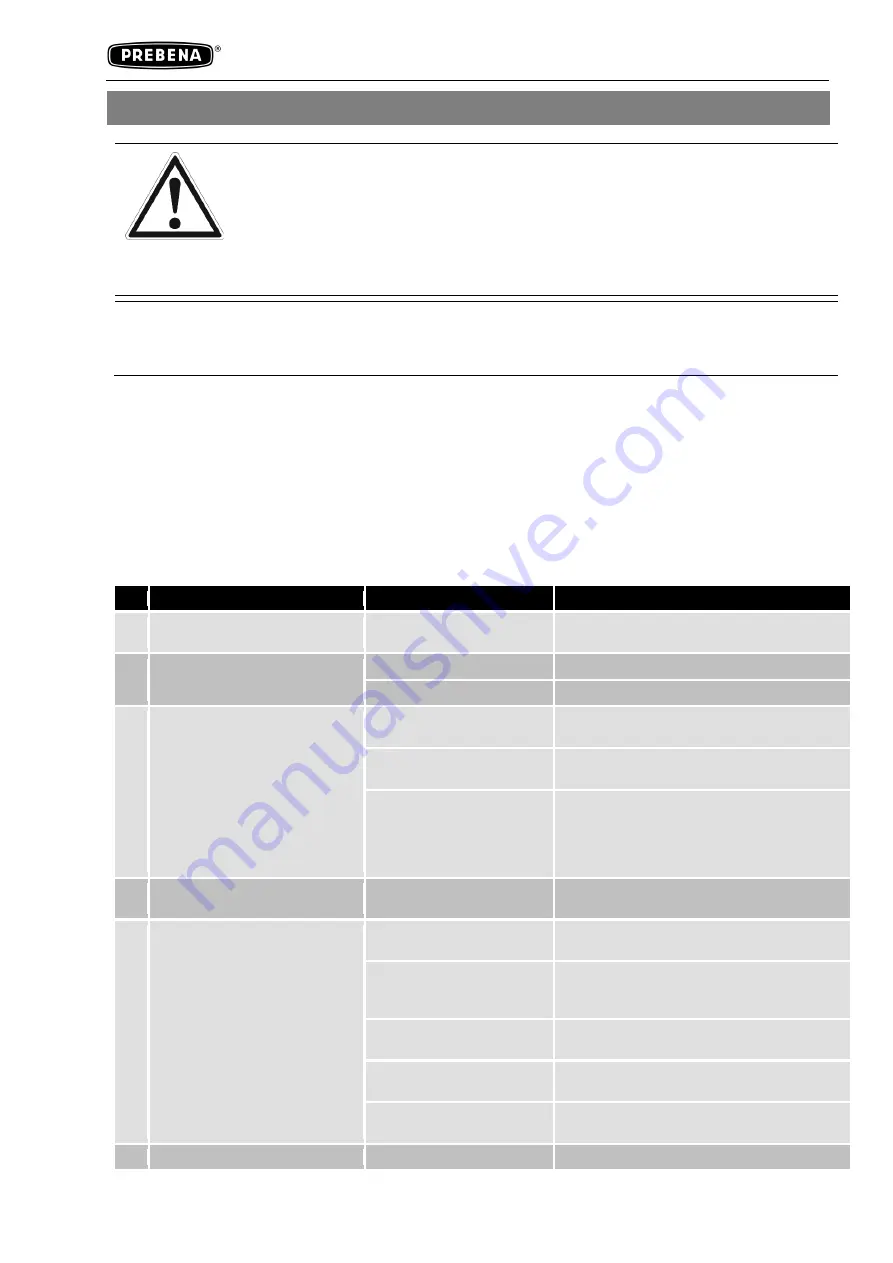

Overview of faults

The following overview lists possible faults and the necessary measures.

Fault

Possible cause

Corrective measure

A

Motor does not start

Fault in the electric power supply

Check cable, fuse,

compare motor data with the power system.

B

Motor running irregularly

Tension at the drive V-belt too low

Adjust tension on drive V-belt.

Drive V-belt worn

Replace drive V-belt.

C

Motor protecting switch turns off during

operation.

Inadequate voltage supply due to

weak power system

Switch off additional loads/consumers where possible

Extension cable too long or cross-

section too small

Use suitable cable.

Motor protecting switch has tripped

due to overheating

Interrupt current supply via the pressure switch.

Allow compressor to cool down.

If the motor protecting switch trips again on

renewed starting:

Notify aftersales service (see page 27).

D

Heavy V-belt abrasion (black deposit on

belt guard)

Tension at the drive V-belt too low

Adjust tension on drive V-belt.

E

Compressor does not reach final pres-

sure.

Lines and / or manual venting leak-

ing.

Tighten, seal and clean screw fittings.

Notify aftersales service (see page 27).

Venting screw fitting of final pres-

sure safety valve not in operating

position.

Unscrew out venting screw fitting fully.

Final pressure safety valve blows

off too early.

Replace valve.

Notify aftersales service (see page 27).

Piston rings seized or worn.

Free up or replace piston rings.

Notify aftersales service (see page 27).

Piston clearance too large.

Check piston clearance and replace parts.

Notify aftersales service (see page 27).

F

Delivery output drops.

Pipes leaking.

Tighten screw fittings.