Compressor preparation

13

ATTENTION!

Damaged pressure and cooling lines can burst and cause damage to property due to compressed air

escaping.

Check the pressure and cooling lines for damage before connecting them.

Checking the function

To ensure that the compressor is functioning correctly, proceed as follows when starting it for the first time:

Operate the compressor only in cool, low-dust, dry and well ventilated rooms.

The ambient temperature may not be colder than +5 °C or hotter than +40 °C.

To prevent damage to the compressor, make sure the standing surface exhibits an inclination in the

transverse and longitudinal directions of no more than 15°.

Make sure the minimum distance of 50 cm between the compressor and any potential obstacle is main-

tained for the free flow or air.

Check before starting that the system voltage and the line frequency match the figures indicated on the

compressor rating plate.

Make sure the retaining bar is in the operating position.

ATTENTION!

Operation from a power supply that does not meet the above-mentioned requirements can lead to dam-

age to the compressor.

Only connect the compressor to a suitable power supply.

ATTENTION!

Observe the danger notes in the chapter on 'Safety' from page 6 ff.

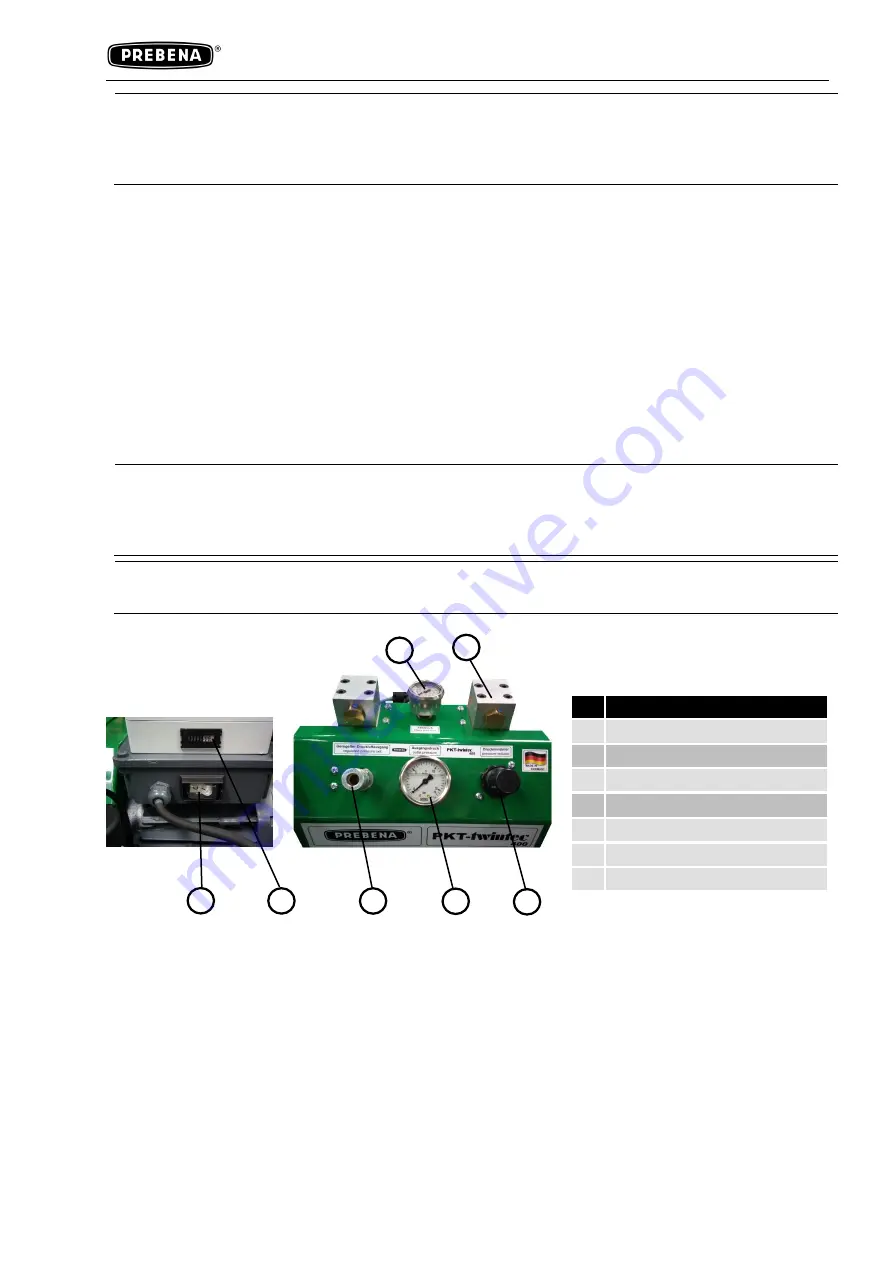

Operating elements:

Connect the compressor to the power supply.

Extension cables must have a minimum cross-section of 2.5 mm² and may not exceed 25 m in

length.

Switch on the compressor at the ON/OFF switch (1) to start the compressor.

Allow the compressor to run at no load until the final pressure is reached.

Check the following properties:

Does the pressure rise at the pressure gauge for filling pressure (3)?

Does the compressor switch off automatically when the end pressure is reached (see Technical specifica-

tions from p. 8)?

No. Explanation

1

ON/OFF switch

2

Operating hour counter

3

Pressure gauge for filling pressure

4

Filling valves (cylinder mounting)

5

Regulated compressed-air outlet

6

Pressure gauge for outlet pressure

7

Pressure reducer

1

2

3

4

5

6

7