PREBENA

Wilfried Bornemann GmbH & Co. KG

BEFESTIGUNGSTECHNIK

– FASTENING TECHNOLOGY

21

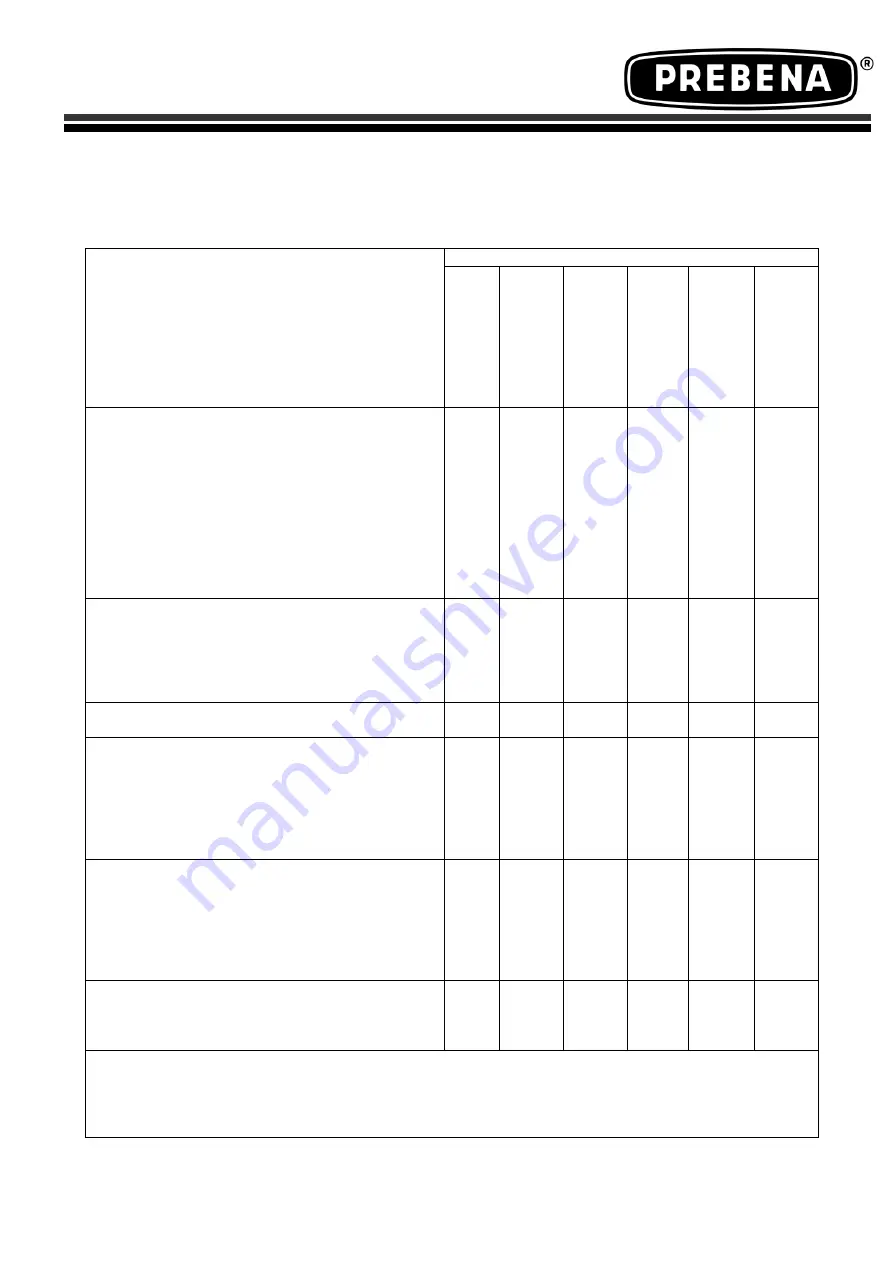

8.3

Maintenance instructions

To ensure the continuous and safe operation of the compressor, follow the

maintenance instructions as specified below in

Table 1

.

Table 1

Action to be performed

Maintenance schedule

Daily

(WD)

500

Hours

(W)

2,000

hours

(Min.

twice

per

year)

4,000

hours

(Min.

once

per

year)

8,000

hours

(Min.

once

every

two

years)

20,000

hours

(Min.

every

six

years)

1

. Visual inspection of the compressor for

mechanical damage, strange noises and

knocking noises, oil leaks. If present, rectify any

errors.

(8.3.14)

2

. Oil level check. If necessary, refill.

(8.3.1)

3

. Check the measured values and the operation

of devices and equipment.

4

. Check pneumatic connections for tightness and

tighten if necessary.

(8.3.13)

5

. Check the oil in the inspection window of the oil

separator.

(8.3.1)

+

+

+

+

+

+

1

. Check the radiator. If necessary, clean with

compressed air.

2

. Check the purity of the oil (intense dark colour)

and change oil if necessary.

(8.3.1)

3.

Check the connectors of electrical devices or

power cables.

(8.3.14)

–

+

+

+

+

+

1

. Replacement of the air filter;

(8.3.9)

2

. Belt tension check. If necessary, adjust.

(8.3.7)

-

+

+

+

+

+

1

. Oil change.*

(8.3.3)

2

. Replacement of the oil filter.*

(8.3.10)

3

. Replacement of the filter-oil separator

(separator).

(8.3.11)

4

. Safety valve check. Replace if necessary.

(8.3.15)

5

. Checking of the pressure vessel condition.

–

–

–

+

+

+

1

. Replacement of seals.

2

. Replacement of the seal set at the suction valve.

3

. Replacement of the seal set at the minimum

pressure valve.

4

. Replacement of the seal set at the thermostat.

5

. Replacement the seal set at the screw conveyor

unit.

–

–

–

–

+

–

1

. Replacement of the complete set of belts on the

screw conveyor unit.

(8.3.6)

2

. Replacement of the bearings at the electric

motor.

–

–

–

–

–

+

NOTE:

1 For the tasks specified in the schedule that are planned for longer time intervals, the work to be

performed at the shorter intervals is included.

2 * Perform the first oil change and oil filter replacement after 500 operating hours and the next after

4000 operating hours, but at least once per year.

Summary of Contents for SK-15-10

Page 33: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANHANG...

Page 35: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 35...

Page 36: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 36...

Page 122: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 APPENDIX...

Page 127: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 128: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...

Page 214: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANNEXE...

Page 219: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 220: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...