PREBENA

Wilfried Bornemann GmbH & Co. KG

BEFESTIGUNGSTECHNIK

– FASTENING TECHNOLOGY

24

8.3.6

Replacement of the belt

When replacing the belt, the following is required:

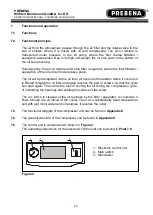

a) Remove the right cover of the compressor housing and the protective device.

b) Loosen the four screws of the motor platform.

c) Reduce the belt tension by moving the motor platform in the direction of screw

conveyor unit

d) Remove the belt.

e) Clean the grooves of the pulley with a cleaning cloth and install the new belt.

f) Now increase the tension by moving the electric motor platform away from the

worm screw. Ensure that the belt tension and deflectionare adjusted as shown in

Figure 7

.

g) Tighten the motor platform by tightening the screws firmly.

h) Place the protection device and the cover back on the compressor housing.

8.3.7 Checking the belt tension

The belt tension adjustment is performed in accordance with

Point 8.3.6

.

The power of the electric motor is transmitted by means of the contact of the belt with

the pulleys. To ensure normal operation, all contact surfaces must be clean and the

belt must be fully taught and set to the correct tension / deflection.

The belt tension should be checked after assembly and periodically during operation,

especially if the compressor has not been used over a period of at least one week.

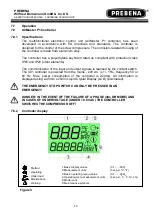

The belt deflection should be adapted and adjusted using a dynamometer, a string

and a ruler

(Figure 7).

The power is transmitted via the belt, whereby frictional forces are generated

between the belt and pulleys, transferred from the electric motor to the drive of the

screw assembly. To ensure normal operation, all surfaces of belts and pulleys must

be kept clean and tightened to the correct pressure.

The belt tension must be checked after assembly and periodically during operation,

especially if the compressor has not been used over a period of at least one week.

3 to 5 operating hours after the belt change, check the tension, since the belt has

been subject to intensive expansion during this period, which may lead to a friction-

induced slippage and thus to power loss and damage.

For compressors up to 15 kW: The belt must be tightened and may only yield up to a

maximum of 5-6 mm at an applied force (F) of 30 N

(Figure 7)

.

Summary of Contents for SK-15-10

Page 33: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANHANG...

Page 35: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 35...

Page 36: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 36...

Page 122: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 APPENDIX...

Page 127: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 128: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...

Page 214: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANNEXE...

Page 219: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 220: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...