PREBENA

Wilfried Bornemann GmbH & Co. KG

BEFESTIGUNGSTECHNIK

– FASTENING TECHNOLOGY

6

4

Purpose

4.1

The compressor is used to generate compressed air for the supply of pneumatic

equipment, devices and tools in industry and in the craft sector. Depending on the

type, the compressor may not be equipped with a filter to remove moisture or aerosol

(spray), liquid and vaporised oil particles. In order to produce particularly pure

compressed air, the installation of an appropriate filter / dryer is required.

4.2

The compressed air produced by the unit may not be used for pharmaceutical, food

processing or sanitary purposes without subsequent special filtering.

4.3

The compressors are designed for continuous operation.

5

Specifications

5.1

The compressor has been designed and manufactured in accordance with the

general safety requirements and standards relating to this type of device and in

accordance with applicable technical regulations.

5.2

The main technical specifications for the compressor areprovided in

Appendix B

.

5.3

For the technical specifications of the drive belt for the compressor, please refer to

Appendix B

.

5.4

For the technical specifications of the electric motors, please refer to

Appendix B

.

NOTE: THE BUILT-IN ELECTRIC MOTOR HAS AN EFFICIENCY RATING OF IE2

FOR INSTALLATION IN A COMPRESSOR.

5.5

For the technical specifications of the screw unit, please refer to

Appendix B

.

5.6

The compressor must be connected to a three phase power source (400V). The

voltage and nominal values for the power supply and the current frequency are

provided in

Appendix B

of this user manual.

5.7

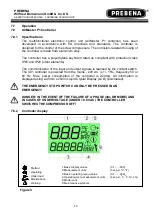

The pressure within the air / pressure vessel is automatically controlled by the

electronic control unit and the compressor control unit.

5.8

The compressors operate reliably at ambient temperatures from +5 ° С to +40 ° С,

and at a maximum relative humidity of no more than 90%.

6

Commissioning

6.1

General information

Unpack the compressor carefully and check that the delivery is complete. Make sure

that there are no visible signs of shipping damage.

- Remove the housing panels of the compressor.

- Perform a visual inspection for oil or other leaks.

- Check the oil level through the inspection window of the oil indicator.

It is recommended that the oil be refilled or replaced asdescribed in

Point 8.3.3

of

this manual. Spare parts (oil filter, air filter, oil separator and a series of belts)

required for technical maintenance must be obtained from the dealer or manufacturer.

Summary of Contents for SK-15-10

Page 33: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANHANG...

Page 35: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 35...

Page 36: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 36...

Page 122: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 APPENDIX...

Page 127: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 128: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...

Page 214: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANNEXE...

Page 219: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 220: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...