Model PD6200 Analog Input Rate/Totalizer

Instruction Manual

70

Serial Communications (

serial

)

The meter is equipped with serial communications capability as a stan-

dard feature using PDC Serial Communication Protocol.

To communicate with a computer or other data terminal equipment, an

RS-232 or RS-422/485 adapter option is required; see

Ordering Informa-

tion

on page 7 for details.

Warning!

Do not connect any equipment other than Precision

Digital’s expansion modules, cables, or meters to the

RJ45 M-LINK connector. Otherwise damage will occur

to the equipment and the meter.

Note: More detailed instructions are provided with each optional serial

communications adapter.

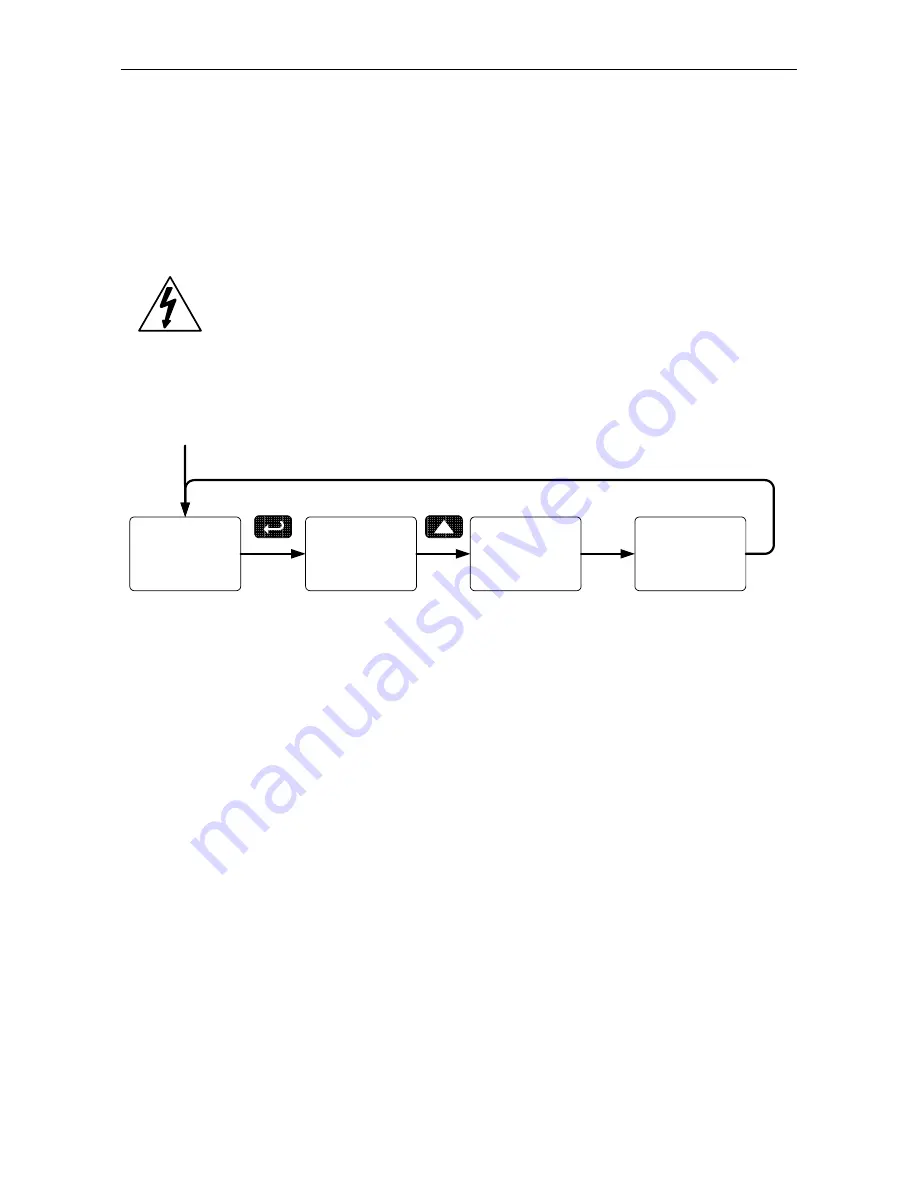

baud

Serial

Address

Serial

tr dly

Serial

serial

When using more than one meter in a multi-drop mode, each meter must

be provided with its own unique address. The address may be pro-

grammed from 1 to 247. The transmit delay may be set between 0 and

199 ms.

The PD6200 can also be connected to another PD6200 allowing the

user to copy all the settings from one meter to another, using the

Copy

function.