Model PD650 Large Display Process Meter

Instruction Manual

81

Pump Alternation Control

For pump control applications where two similar pumps are used to control the

level of a tank or a well, it is desirable to have the two pumps operate alternately.

This prevents excessive wear and overheating of one pump over the lack of use

of the second pump.

A pair of relays can be set up to alternate every time an on/off pump cycle is

completed. set points and reset points can be programmed, so that first pump on

is the first pump off.

Pump Alternation Typical Application

Pump alternation setup

1. All relays are set up to respond to process/rate.

2. Relays 1 and 2 are set up to alternate.

3. Relays 3 and 4 are programmed for low and high alarm indication,

respectively.

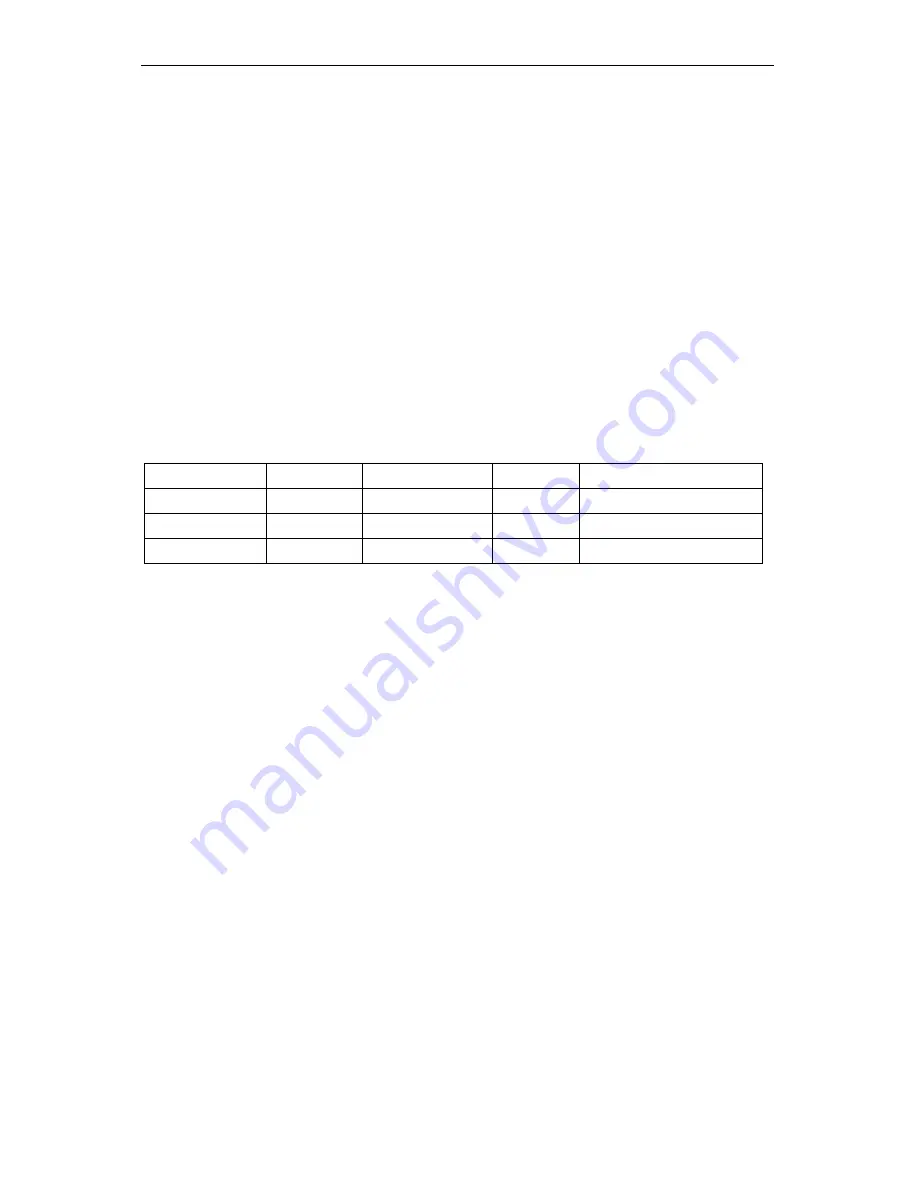

Set and reset point programming

Set point 1

30.00

Reset point 1

10.00

Controls pump #1

Set point 2

35.00

Reset point 2

5.00

Controls pump #2

Set point 3

4.00

Reset point 3

9.00

Controls low alarm

Set point 4

40.00

Reset point 4

29.00

Controls high alarm

Pump alternation operation

1. Pump #1 turns on when level reaches 30.00, when level drops below 10.00

pump #1 turns off.

2. The next time level reaches 30.00, pump #2 turns on, when level drops

below 10.00 pump #2 turns off.

3. If the level doesn’t reach 35.00 pump #1 and pump #2 will be operating

alternately.

4. If pump #1 can’t keep the level below 35.00 pump #2 will turn on at 35.00,

then as the level drops to 10.00 pump #1 turns off, pump #2 is still running

and shuts off below 5.00.

5. With set and reset points of pump #2 outside the range of pump #1, first

pump on is the first pump to go off. This is true for both pumps.