24

Copyright © 2020 Quality Machine Tools, LLC

PM-1228VF v3 2020-10

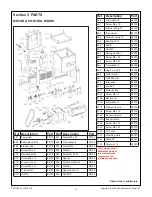

LUBRICATION — OILERS

Figure 4-3

Saddle & compound oilers

There are no oilers on the cross-slide other than the leadscrew

oiler on the front flange — apply oil to the cross-slide dovetail

surfaces using a flux brush or similar. Do this on other sliding

surfaces over the entire machine, even if oil has been applied to

the ball oilers.

Figure 4-5

Tailstock oilers

Figure 4-4

Leadscrew and feed shaft oilers

Figure 4-6

Shifter assembly oilers

The two Zerk fittings are intended for oil, not grease. They

may be difficult to get to, in which case one alternative is to

remove the fittings altogether and replace them with (say)

short socket head cap screws, which can be removed to al-

low oil to be squirted directly into the axles. The Zerk screw

threads are M8 x 1, not the more common M8 x 1.25.

Figure 4-7

Shifter assembly pivot

There is no oiler on the pivot axle post: remove

the M6 screw and washer, slide the upper gear

assembly clear, then apply oil directly to the axle.

Figure 4-8

Middle gear oiler

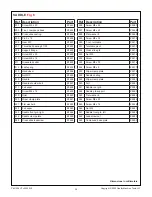

ADJUSTMENT — GIB SCREWS

Figure 4-9

Gib strip schematic