17

PM-1440BV v3 2020-10

Copyright © 2020 Quality Machine Tools, LLC

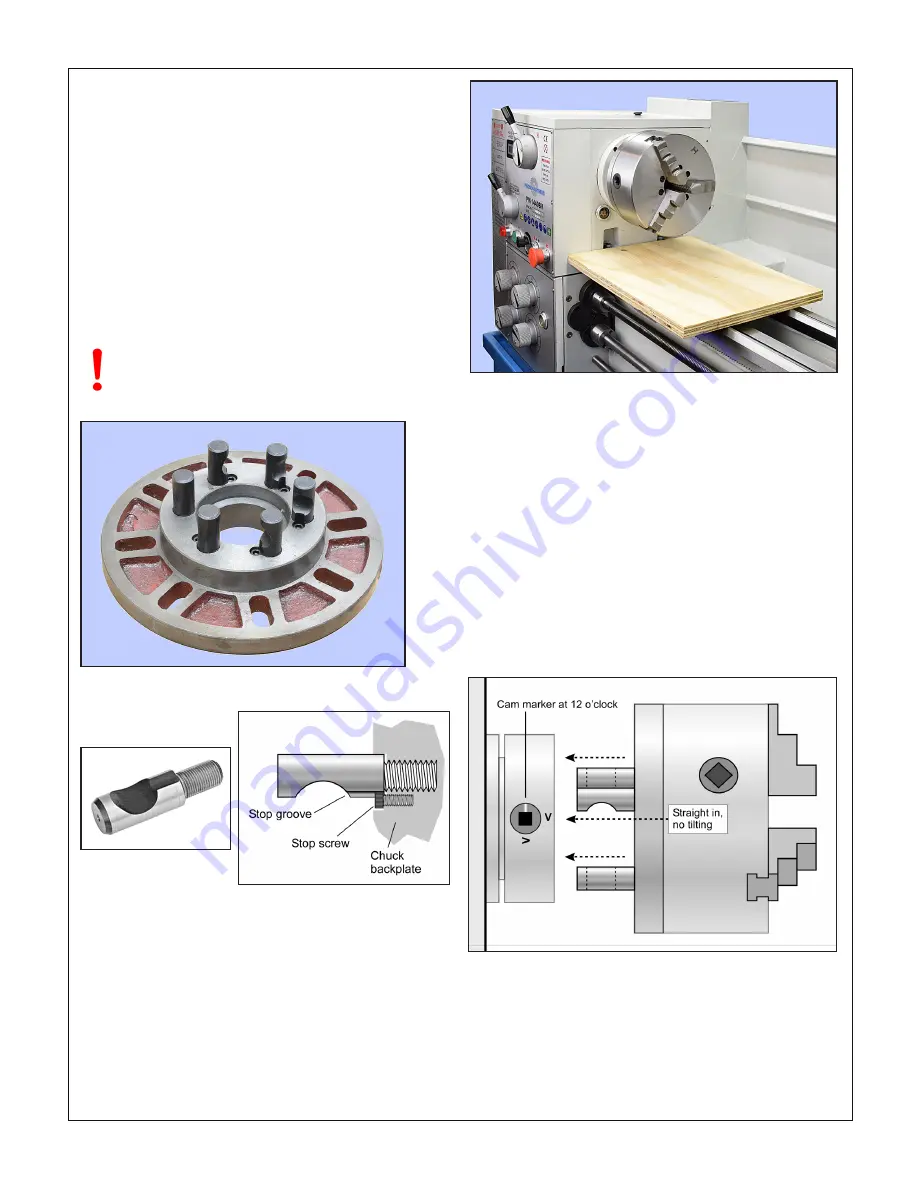

CHUCKS & FACEPLATE

The spindle nose on the PM-1440BV accepts D1-5 Camlock

chucks, faceplates and other work holding devices.

A D1-5 chuck or faceplate is held by six threaded studs, each

with a D-shape crosscut to engage a corresponding cam in the

spindle nose, Figures 3-21, 3-22. The function of the cams is

to pull the chuck backplate inward to locate its internal taper

firmly on the spindle nose.

Alongside each stud is a stop screw, the head of which fits

closely in a groove at the threaded end of the stud. The func-

tion of the stop screw is not to clamp the stud in place, but

instead to prevent it from being unscrewed when the chuck is

out on the bench.

TO INSTALL A CHUCK

Disconnect the 220V supply from the lathe!

D1-5 chucks and faceplates are heavy, some more than 30

lb. They will cause serious damage if allowed to fall. Even if a

chuck is light enough to be supported by one hand, the lathe

bed should be protected by a wood scrap, as Figure 3-23.

Some users add packing pieces, even custom-made cradles,

to assist “straight line” installation and removal.

All stop screws must be present & fully tightened!

Camlock action can jam any stud lacking a stop

screw — a serious problem.

Figure 3-21

D1-5 faceplate

Figure 3-22

Camlock stud

Before installing make certain that the mating surfaces of the

chuck/faceplate and spindle are

free of grit and chips

.

The cams on the spindle are turned with a square-tip wrench

similar to the chuck key (may be same tool in some cases).

Recommended procedure:

1. Select the high speed range

H

to allow easier hand rotation

of the spindle.

2. Turn the spindle by hand, checking that all six cam markers

are at 12 o’clock.

3. While

supporting its full weight

, install the chuck without

tilting, see Figure 3-24, then gently turn each of the cams

clockwise

— snug, firm, but not locked in this first pass.

Figure 3-23

Protect the lathe bed

4. Check that each of the cam markers lies between 3 and

6 o’clock, between the two Vees stamped on the spindle,

Figure 3-25.

5. If any cam marker is

not

within the Vees, first be sure

that there is

no gap

between chuck backplate and spin-

dle flange. Also, remove the chuck to inspect the studs —

Figure 3-24

Installing a Camlock chuck