11

Copyright © October 2017 Quality Machine Tools, LLC

PM-1440E-LB 11-13-17 V1

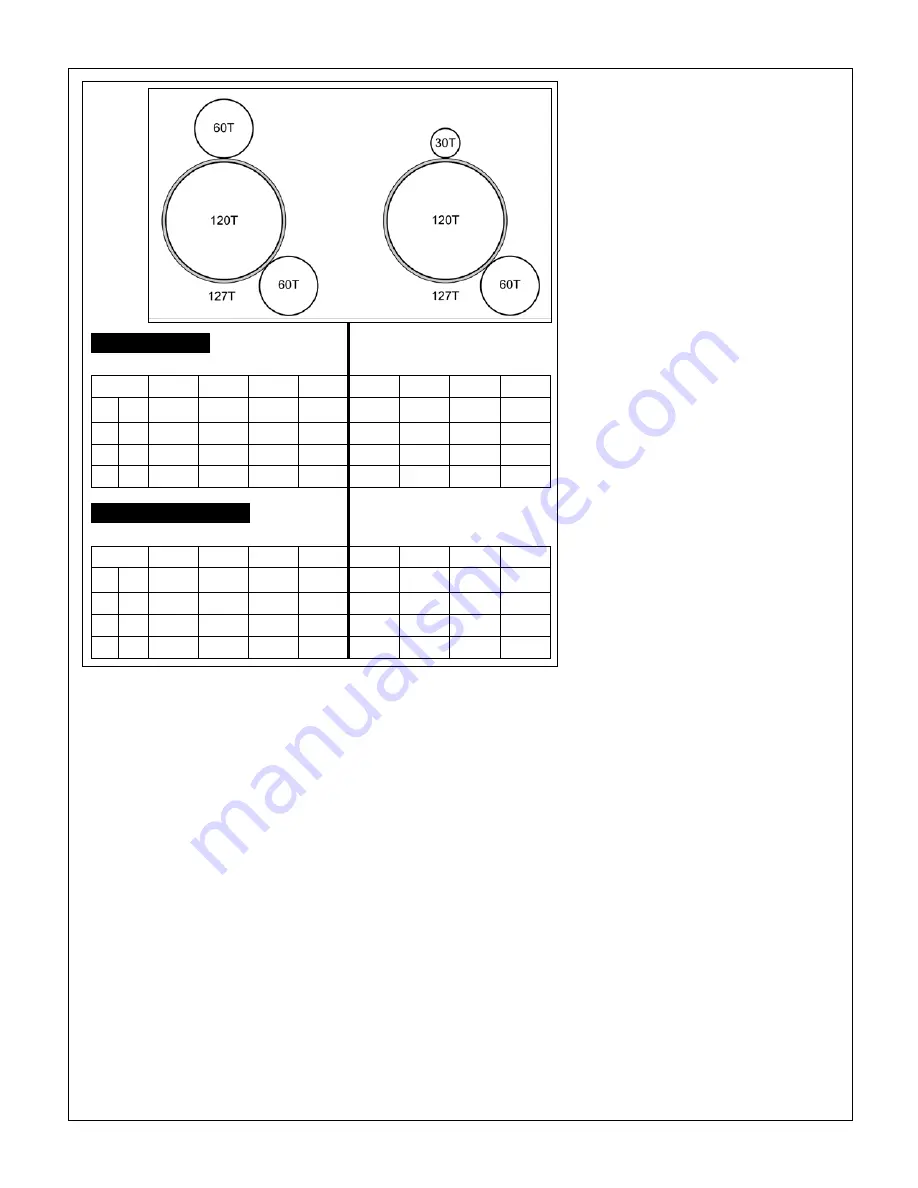

Figure 3-6

Power feed rates (inches per spindle rev)

For any given selection, saddle motion is approximately 3 times cross-slide motion.

FEEDSHAFT CLUTCH

The clutch shown in Figure 3-7 disengages the power feed if

the saddle or cross-slide hits an obstruction when power feed-

ing, thus minimizing the potential for damage. This could be

the result of either an accidental event, or deliberately stopping

the saddle at a precise location set by the saddle stop, Figure

3-8.

T

S

R

V

T

S

R

V

A D

0.0187 0.0175 0.0140 0.0112 0.0094 0.0087 0.0070

0.0056

B D

0.0094 0.0087 0.0070

0.0056

0.0047 0.0044 0.0035 0.0028

A C

0.0047 0.0044 0.0035 0.0028 0.0024 0.0022 0.0017 0.0014

B C

0.0024 0.0022 0.0017 0.0014 0.0012 0.0011 0.0009 0.0007

T

S

R

V

T

S

R

V

A D

0.0548 0.0512 0.0411 0.0328 0.0274

0.0256

0.0205

0.0164

B D

0.0274

0.0256

0.0205

0.0164

0.0137 0.0128 0.0102 0.0082

A C

0.0137 0.0128 0.0102 0.0082

0.0069 0.0064

0.0051 0.0041

B C

0.0069 0.0064

0.0051 0.0041 0.0034 0.0031 0.0025 0.0020

SADDLE FEED

Inches/spindle revolution

CROSS-SLIDE FEED

Inches/spindle revolution

EXTERNAL GEAR SWAPPING

The 120T and 127T gears in Figures 3-5 are called

transpos-

ing gears

. They allow a standard-thread leadscrew — in this

case 8TPI — to cut metric threads.

For U.S. (TPI) thread cut-

ting there is no transposing requirement

— the 127T gear

acts only as an idler, transferring drive directly from the head-

stock to the gearbox.

Any change to the drive train typically calls for one or both

of the upper and lower gears to be exchanged for a larger or

smaller gear. This will require the transposing gears to be re-

positioned. The procedure for this is:

1.

Remove the hex nuts from the upper and lower gear shafts.

2. Remove the upper and lower gears, washers and keys.

3.

While holding the gear support casting (quadrant) with one

hand, loosen its anchor nut and clamp screw. Allow the

casting to swing downward.

4.

Loosen the hex nut securing the transposing gear axle to

the support casting.

5. Install the lower gear.

6.

For

power feeding

or

U.S. (TPI) thread cutting

, bring

the larger transposing gear (127T) into mesh with the low

-

External

gears

er gear, running a scrap of printer paper (about 0.004")

trapped between the two to set them at the correct sepa-

ration. For

metric thread cutting

, mesh the smaller trans-

posing gear (120T) with the lower gear, Figure 3-9.

7. Tighten the transposing gears in position, then remove the

paper scrap. Check again for working clearance between

the gears.

8. Install the upper gear.

9. Swing the gear support casting upward to mesh the 127T

gear with the upper gear, again using a paper scrap for

separation.

10. Tighten the gear support casting.

11. Lubricate the gears.