23

Copyright © October 2017 Quality Machine Tools, LLC

PM-1440E-LB 11-13-17 V1

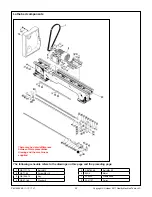

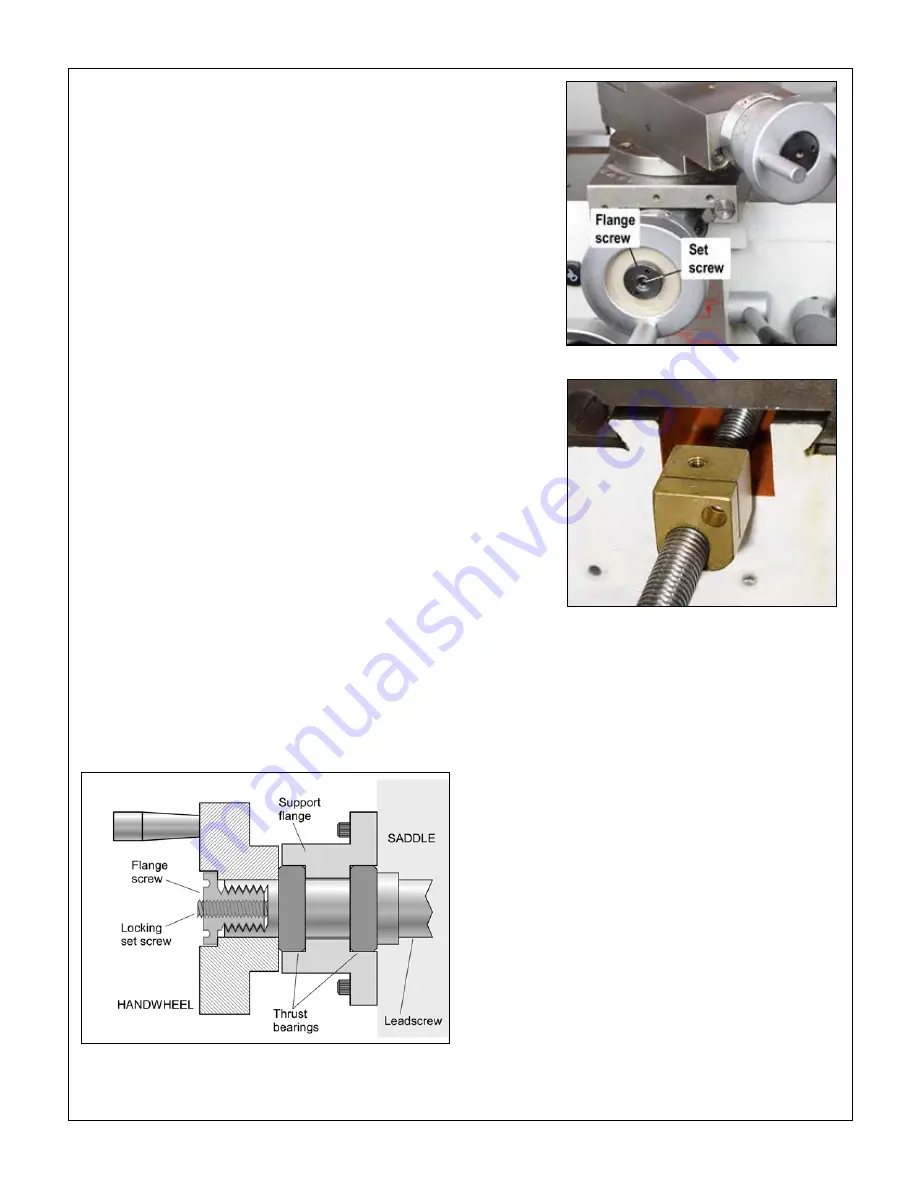

CROSS-SLIDE & COMPOUND BACKLASH

When alternating between clockwise and counter clockwise

rotation, the cross-slide handwheel may move freely a few de-

grees but the cross-slide table stays put. There may also be

similar lost motion in the compound. The acceptable amount

depends on the user, but 0.005” is generally a good compro-

mise. Smaller numbers are possible, but overdoing it can lead

to premature wear of leadscrew and nut.

Lost motion is due to two factors: 1. End-float (in/out move

-

ment of the handwheel) caused by insufficiently tight coupling

of the leadscrew and thrust bearings. 2. Wear in the leadscrew

nut.

Factor #1 is correctable in both the cross-slide and compound.

Leadscrew handwheels on the PM-1440E-LB — cross-slide,

compound and tailstock — are attached in a similar way, Fig-

ure 4-13. The handwheel is locked to the leadscrew shaft by

a key (not shown). It is held in place by a flange screw in a

threaded well at the outer end of the leadscrew shaft. An in-

ternal locking set screw, bottomed in the well, prevents loos-

ening of the flange screw. To correct backlash due to loose

coupling between leadscrew and thrust bearings, back out the

set screw a turn or two, then tighten the flange screw using

a pin vise or needle-nose pliers. Do not tighten to the point

where the thrust bearings are over-compressed, resulting in

uneven motion. Back off for smooth rotation, with no appre

-

ciable end-float. Re-tighten the set screw. This tends to back

out the handwheel a small amount, so check end-float again.

Factor #2 is correctable in the cross-slide by compressing

the leadscrew nut, Figure 4-14. Remove the compound from

the cross-slide, then remove the socket head screw secur-

ing the cross-slide to the leadscrew nut. Turn the cross-slide

handwheel clockwise to drive the nut backward until it can be

worked on at the back. Ii not already installed, insert an M6 x

1 socket head screw, approximately 15 mm long, then tighten

the screw as necessary. Don't overdo this — a 45 degree turn

of the screw represents a backlash take-up of about 0.005".

The compound leadscrew nut is not adjustable.

Figure 4-13A

Handwheel attachment schematic

Figure 4-14

Cross-slide leadscrew nut

(representative)

Figure 4-13B

Handwheel attachment