24

PM-1440E-LB 11-13-17 V1

Copyright © October 2017 Quality Machine Tools, LLC

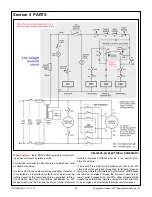

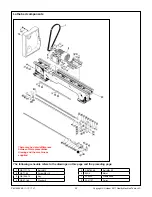

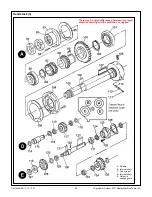

DRIVE TRAIN

Double-groove pulleys co

nnect the motor to the gearbox. Belt

tension will not usually require attention. If necessary, loosen

the three hex head bolts securing the motor, Figure 4-17. Ad

-

just the motor to re-tension. Make certain the motor is properly

aligned, then re-tighten the bolts.

Figure 4-17

Vee belts

Firm finger

pressure here

should deflect

the Vee belt

about 1/4"

Figure 4-18

Motor attachment bolts

(representative)

Do not loosen the bolts securing the motor to this casting!

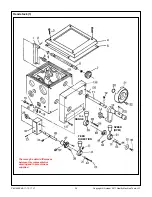

TAILSTOCK BED CLAMP

The angular position of the bed clamp lever is adjustable. Slide

the tailstock toward the headstock to expose the threaded

stop screw at the right hand end of the bed. Remove the stop

screw, then

very carefully slide

the tailstock to the right, just

far enough to allow access to the hex nut below the tailstock

bed plate. Tighten the nut as necessary.

Figure 4-15

Footbrake microswitch

(LH stand cabinet)

Figure 4-16

Brake assembly

(representative)

BRAKE ASSEMBLY

The treadle-operated brake does two things: 1. It disconnects

power from the motor, Figure 4-15, and; 2. It expands brake

shoes against the hollowed-out inboard face of the driven pul-

ley.

Inspection of the brake assembly, Figure 4-16, may be a

two-person job, Person A to lock the driven pulley while Person

B removes the socket head screw securing the driven pulley.

The inboard face of the driven pulley (the brake drum) should

show no gouging or irregularities. Minor damage may be cor-

rectable by skimming; otherwise consider replacing the item.

The brake pads should be clean, evenly worn, showing no sign

of oil. Minimum pad thickness is 4.5 mm, about 0.18". If nec-

essary replace the pads by separating them — extending the

springs — then lifting them clear of the retaining studs.