Procedure 5.4 - Drive Input Assembly Adjustments

This procedure ensures that the drive input assembly, the drive belts and the eddy current

magnet are correctly adjusted and aligned. All of the checks described in this procedure must be

performed to ensure proper operation.

1.

Set the on/off switch in the “off” position, remove the A.C. line cord from the A.C. outlet.

WARNING

Before continuing with this procedure, review the Warning and Caution statements listed in

Section One, Things You Should Know.

2.

Remove the rear covers as described in Procedure 7.1.

3.

Remove both stairarms as described in Procedure 7.17.

Input Drive Assembly Axle Alignment

4.

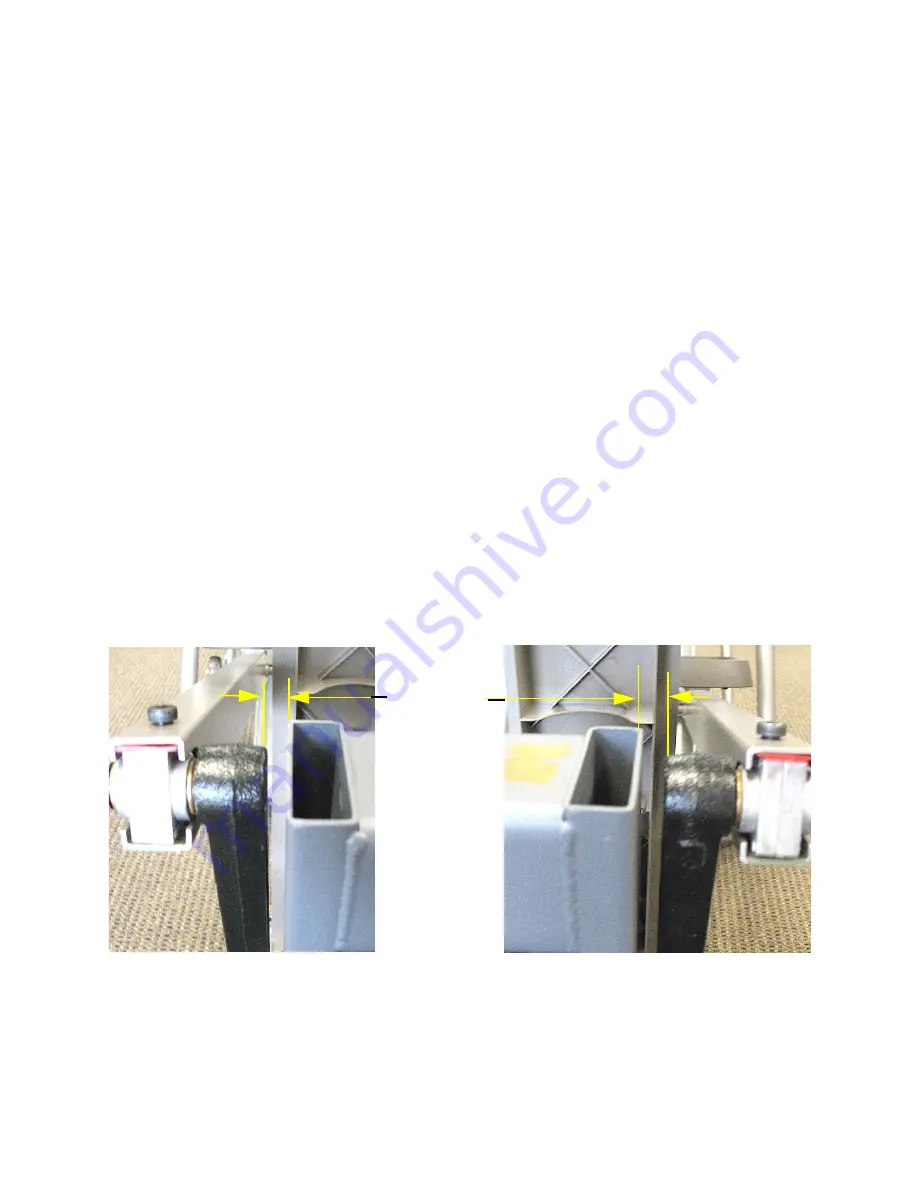

Rotate one of the crankarms to the twelve o’clock position and measure the distance from

the crankarm to the frame weldment. See Diagram 5.6. Rotate the opposite crankarm to the

twelve o’clock position and measure the distance from the crankarm to the frame weldment.

If the two measurements are different by more than 1/16 inch, continue with step 5. If the

two measurements are within 1/16 inch, skip to the “input drive axle to step up pulley axle

alignment” procedure.

Diagram 5.6 - Crankarm to Frame Weldment Measurements

5.

On the side with the larger measurement, loosen the upper pillow block mounting bolt only,

do not loosen the lower pillow block mounting bolt. On the side with the smaller

measurement, loosen both pillow block mounting bolts. See Diagram 5.7. For purposes of

illustration we will assume that the left measurement was larger than the right side

measurement in Diagram 5.7.

Measurement

Summary of Contents for EFX EFX 5.23

Page 79: ...Block Diagram 8 2 5 23 5 25...