©2019 Precor Inc. | Diverging Seated Row RSL 310 | Assembly Guide

11

4

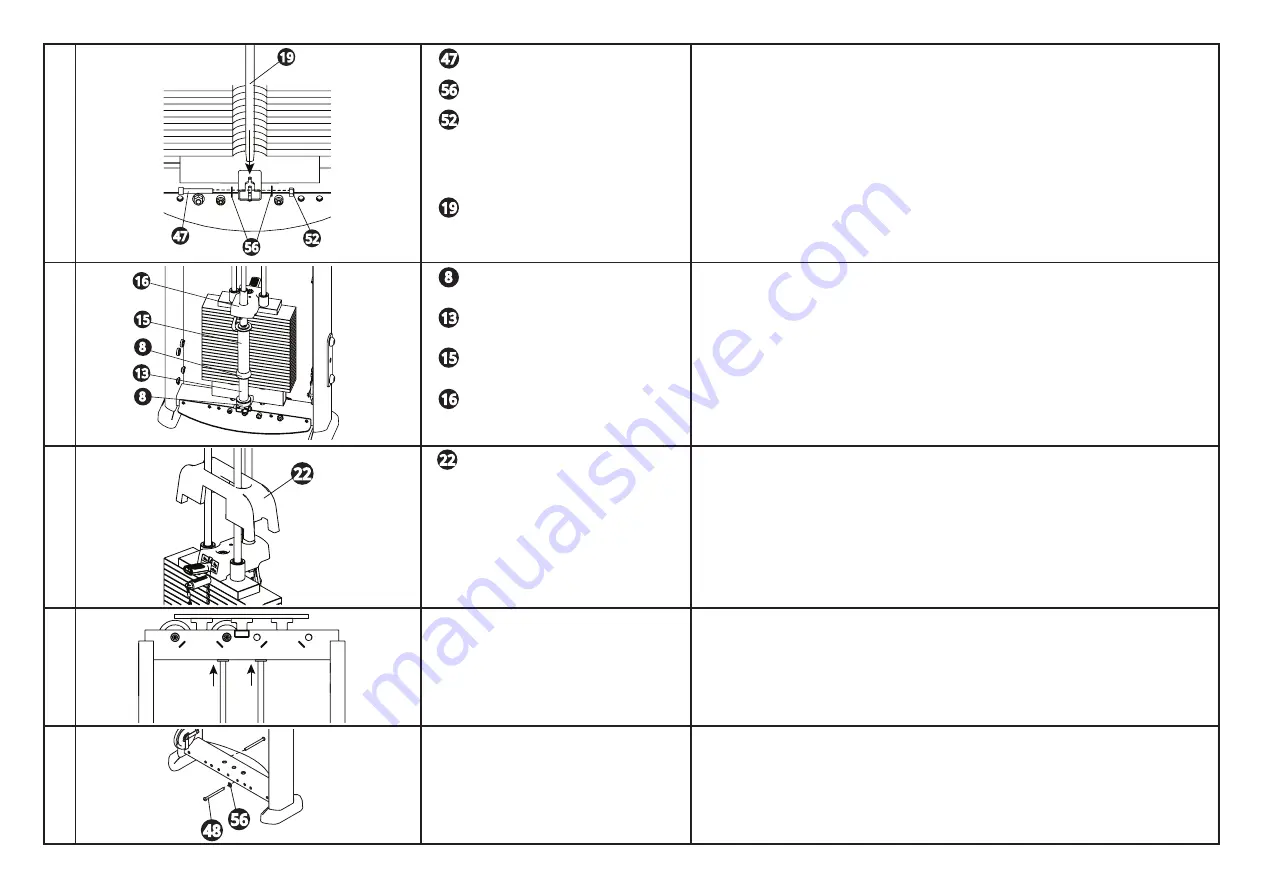

1 M10 x 65 mm SHCS

2 washers, 11 mm

1 M10 nylon lock nut

Tools: Hex wrench, 8 mm

Socket wrench, 17 mm

1 guide rod with cap

Prepare the lower base for the add-on weight assembly. Place the retaining

screw through the bracket on the weight stack spacer.

Remove the cap from the guide rod and place the rod into bracket opening se-

cured by the screw.

5

2 bumpers

1 add-on weight spacer, 5-inch

1 add-on weight

1 add-on weight handle

Place one bumper onto the third guide rod, followed by the add-on weight spac

-

er, another bumper, the add-on weight, and the add-on weight handle.

6

1 counterweight

Place counterweight over front two rods and handle.

7

Straighten the front two guide rods to a vertical position. Have your assistant lift

the guide rods up into the upper part of the frame.

8

Tools: Hex wrench, 6 mm

Torque wrench

While the assistant is holding the rods into the upper frame, reinsert the two

bolts underneath the guide rods in the bottom frame, and secure to the kick

plate. Let the guide rods drop onto the bolts and fully tighten the bolts.

Tighten M10 screws to 32 ft-lb (43 N-m) of torque.

52

19

47

56

16

15

8

13

8

22

13

15

16

19

22

47

52

56

8

56

48