©2019 Precor Inc. | Converging Chest Press RSL 414 | Assembly Guide

9

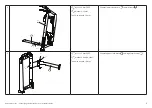

Seat Assembly

Image

Hardware

Instructions

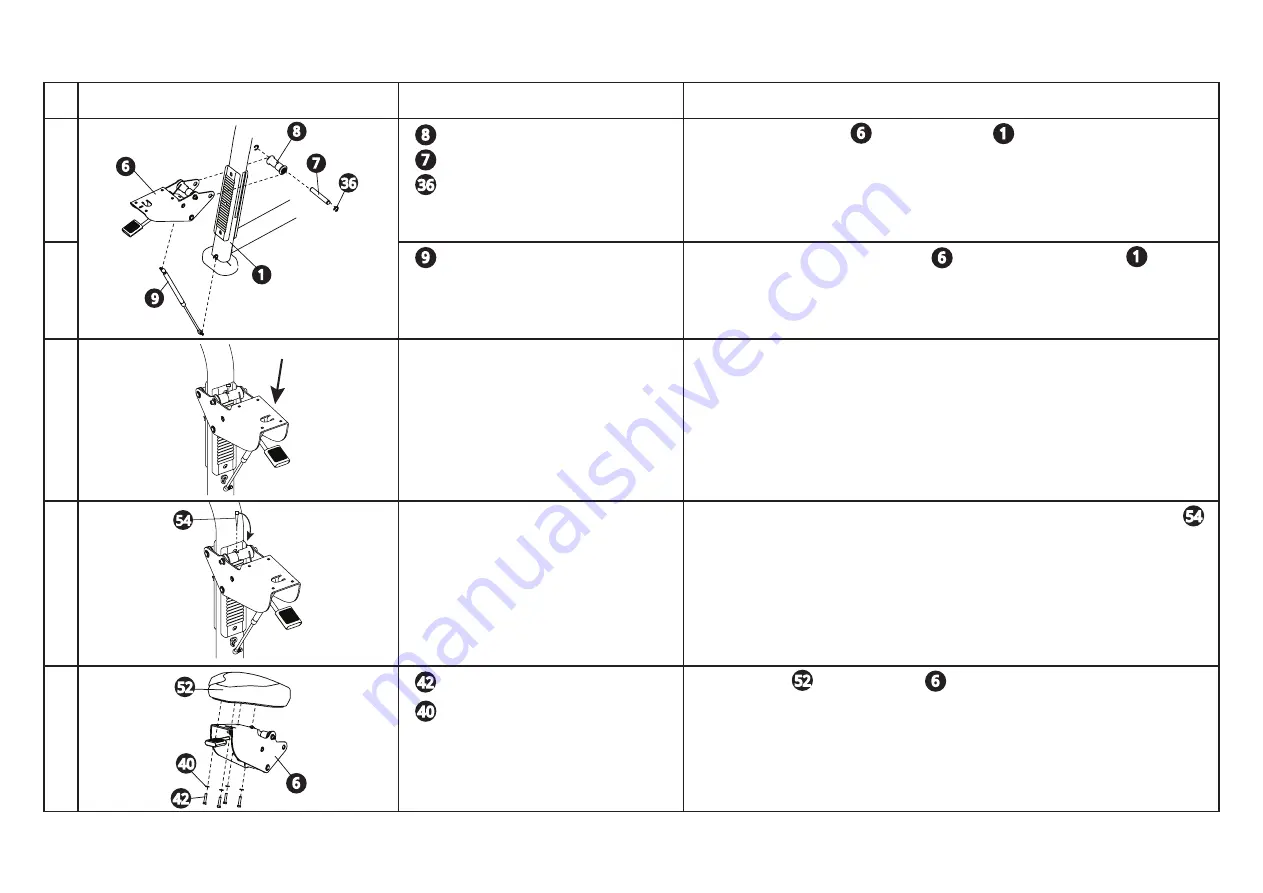

1

1 roller assembly

1 shaft

2 retaining rings, 3/4-inch

Tool: Pliers

Attach the seat assembly to the main frame . Place the roller assembly

between the seat assembly brackets and insert the shaft. Secure each side with

retaining rings.

2

1 gas spring

Snap gas spring into place under seat and at base of main frame . The larg-

er body of the gas spring attaches to the seat.

3

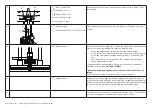

To adjust the roller clearance on the seat assembly, have your assistant apply

downward force on seat.

4

Tools: Two hex wrenches, 8 mm

Preinstalled on the front roller of the seat assembly is a roller adjustment tool .

Continue to apply force to the seat assembly and press the adjustment tool

down-

ward

to turn the roller. Turn until it just contacts the plastic ratchet plate and no

more than 180 degrees. Tighten the socket head screws on the sides of the front

roller (ensure the position of the roller tool does not change).

Remove tool.

5

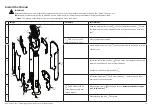

4 hex head screws 5/16 x 1½-inch

4 washers, 9 mm

Tool: Socket wrench, ½-inch with extension

Attach seat pad to seat assembly .

1

6

7

8

9

6

1

6

36

40

42

52

54

54

52

6

40

42

1

8

7

36

9

6