©2019 Precor Inc. | Converging Shoulder Press RSL 515 | Assembly Guide

4

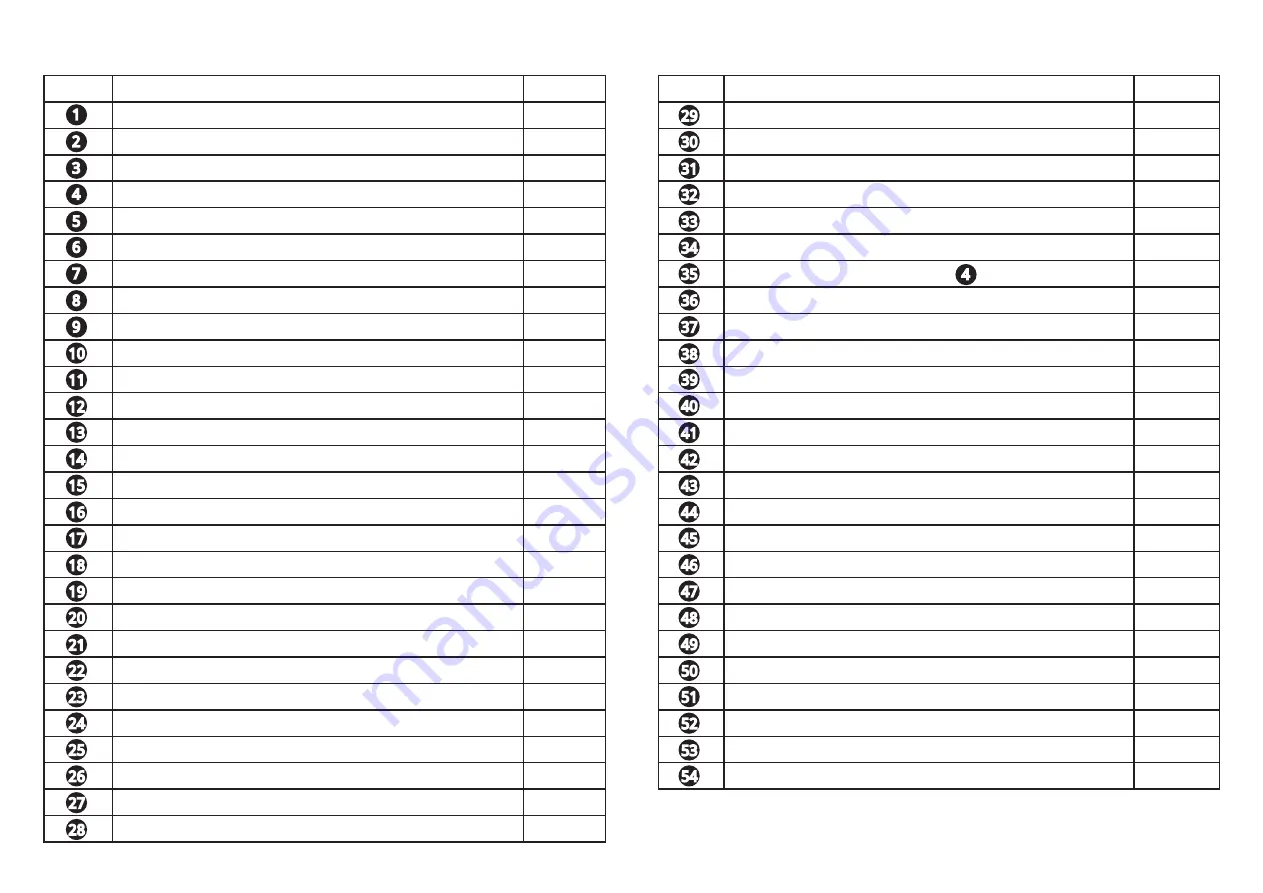

Part #

Name

Quantity

Part # Name

Quantity

Main frame

1

Seat pad

1

Arm, left

1

Back pad

1

Arm, right

1

Weight plates 10 lb (4.5 kg)

19

Seat assembly

1

Weight labels

1

Lower cross brace

1

Collars

2

Upper cross brace

1

End plugs with sleeves

2

Bumpers

4

Roller adjustment tool (attached to Seat assembly)

1

Shaft

1

Washers, 12.2 mm ID x 35 mm OD

2

Roller assembly

1

Washers, rubber, black

3

Gas spring

1

Washers, domed, silver

2

Weight stack tower frame

1

Washer, silver 13.5 mm ID x 35 mm OD

1

Top plate assembly

1

Washers, 9 mm

6

Add-on weight spacer, 2½-inch

1

Hole plugs

2

Add-on weight 5 lb (2.2 kg)

1

Retaining rings, 3/4-inch

2

Add-on weight handle

1

Socket head cap screws (SHCS) M12 x 25 mm

2

Kick plate

1

Socket head cap screws (SHCS) M12 x 35 mm

6

Weight stack spacer, 3-inch

1

Socket head cap screws (SHCS) M12 x 130 mm

2

Guide rods

2

Socket head cap screws (SHCS) M10 x 65 mm

2

Shroud, crown

1

Socket head cap screws (SHCS) M10 x 40 mm

2

Guide rod with cap

1

Button head cap screws (BHCS) M10 x 125 mm

2

Shroud, rear upper

1

Button head cap screws (BHCS) M6 x 15 mm

2

Shroud, front upper placard

1

Hex head screws 5/16-inch x 1½-inch

6

Shroud, rear lower

1

Nylon lock nuts, M12

2

Shroud, front lower

1

Nylon lock nuts, M10

2

Shroud, rear middle

1

Washers, 13 mm

8

Shroud, front middle (left and right)

2

Washers, 11 mm

5

Top tray

1

Shroud, lower pulley cover

1

1

10

11

12

13

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

3

30

31

32

33

34

35

36

37

39

4

40

42

43

44

45

46

47

48

49

6

7

8

9

2

5

14

Parts List

38

41

50

51

52

53

54

4