©2019 Precor Inc. | Prone Leg Curl RSL 606 | Assembly Guide

6

Seat Assembly

Image

Hardware

Instructions

1

2 hex head screws 5/16-inch x 1½-inch

2 washers, 9 mm

Tool: Socket wrench, ½-inch

Attach hip pad to seat frame .

2

4 hex head screws 5/16-inch x 1½-inch

4 washers, 9 mm

Tool: Socket wrench, ½-inch

Attach chest pad to seat frame .

39

47

3

2 M12 x 35 mm FHCS

2 end caps

1 shaft

Tool: Hex wrench, 8 mm

Attach ankle pad arm to pivot arm .

4

2 roller pad rings

Snap roller pad cap rings to ankle roller pad .

5

1 retainer ring

Tool: Retaining ring pliers

Slide roller pad onto ankle pad arm and secure.

3

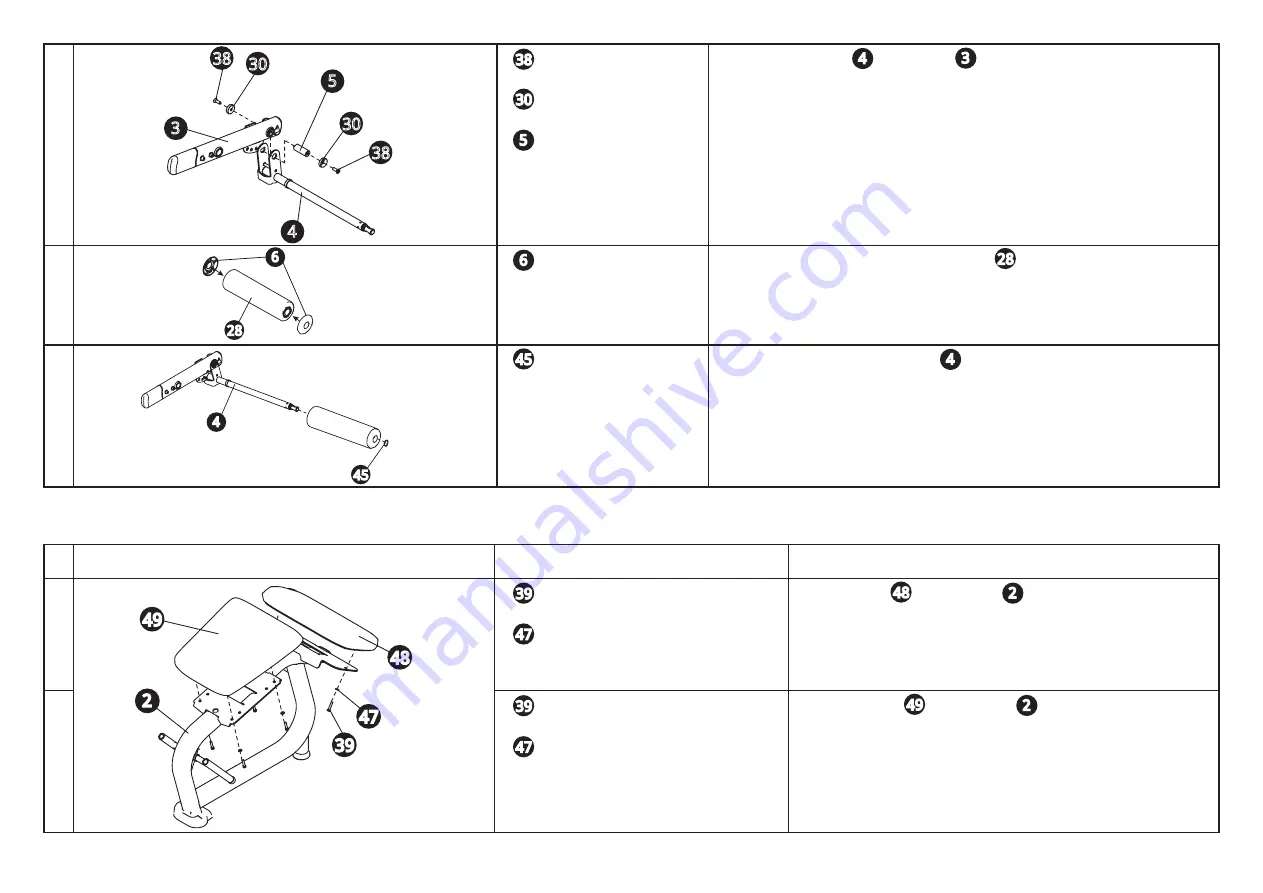

38 30

5

30

4

38

3

30

4

5

38

6

28

4

45

4

45

6

39

47

2

48

49

2

48

2

49

39

47

28