Item 69728 69729

Page 14

For Generator technical questions, please call 1-888-866-5797.

For Engine technical questions, please call 1-800-520-0882.

SAFETY

OPERA

TION

MAINTENANCE

SETUP

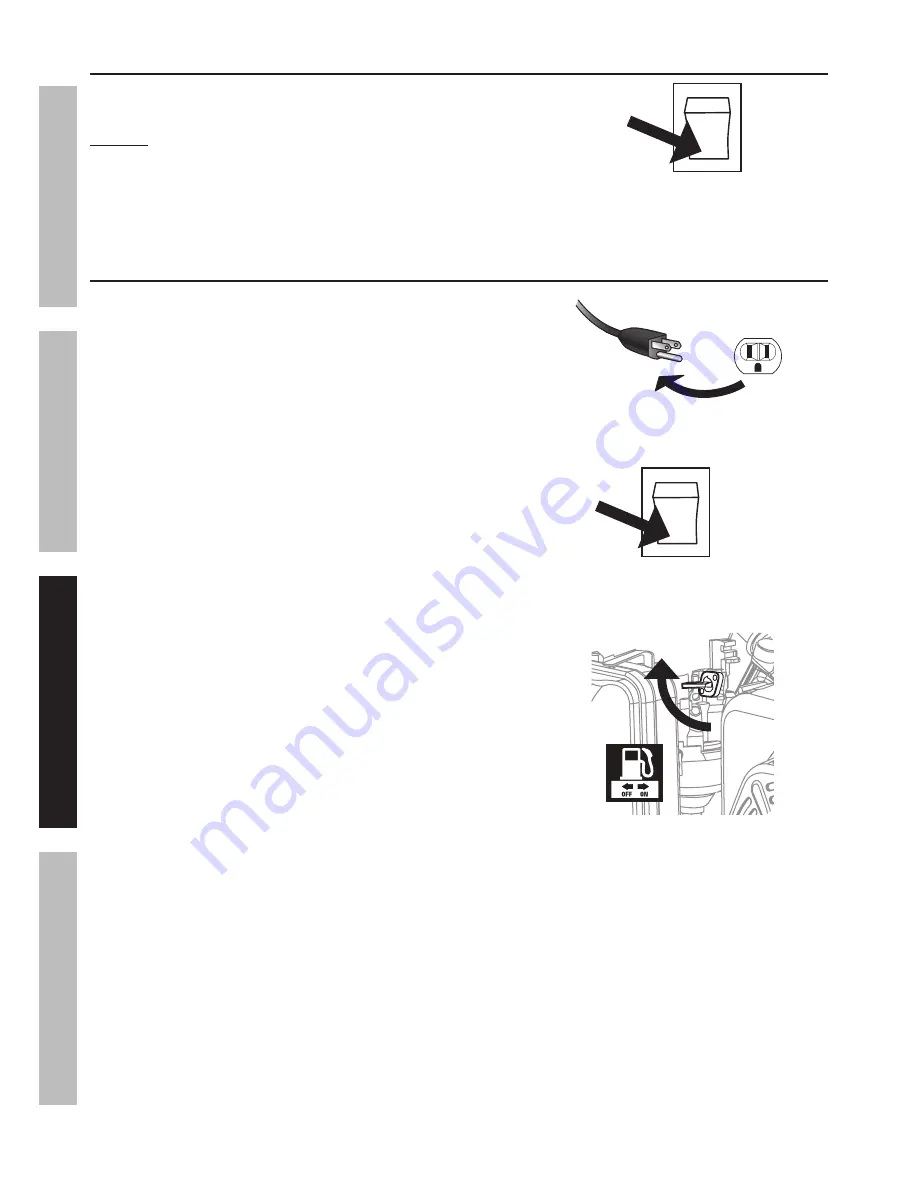

Stopping the Engine in an Emergency

To stop the engine in an emergency,

turn the Engine Switch off.

NOTICE:

Generator shut-off under load may damage

the generator and attached equipment.

Stopping the Engine Under Normal Conditions

1. Before turning off the Engine,

turn off all electrical loads,

then unplug them.

2. Turn the Engine Switch off.

3. Close the Fuel Valve.

OFF

I

O

OFF

I

O

Summary of Contents for 69*729

Page 1: ......