Page 9

For Generator technical questions, please call 1-800-444-3353.

For Engine technical questions, please call 1-800-520-0882.

Item 69671 / 69677

SAFETY

OPERA

TION

MAINTENANCE

SETUP

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

Inspect tool before use, looking for damaged, loose, and missing parts.

If any problems are found, do not use tool until repaired.

Generator Pre-Start Checks

Inspect engine and equipment, looking for

damaged, loose, and missing parts before set

up and starting. If any problems are found,

do not use equipment until fixed properly.

Checking and Filling Engine Oil

CAUTION! Your Warranty is VOID if the engine’s

crankcase is not properly filled with oil before

each use. Before each use, check the oil level.

Do not run the engine with low or no engine

oil. Running the engine with no or low engine

oil WILL permanently damage the engine.

1. Make sure the engine is stopped and is level.

2. Close the Fuel Valve.

3. Clean the top of the Dipstick and the area around it.

Remove the Dipstick by threading it counterclockwise,

and wipe it off with a clean lint free rag.

4.

Full level

Full level

Reinsert the Dipstick without threading it in and

remove it to check the oil level. The oil level

should be up to the full level as shown above.

5. If the oil level is at or below the low mark add the

appropriate type of oil until the oil level is at the

proper level. SAE 10W-30 oil is recommended

for general use. (The SAE Viscosity Grade chart

on page 16 in the Service section shows other

viscosities to use in different average temperatures.)

6. Thread the dipstick back in clockwise.

CAUTION!

Do not run the engine with too little oil.

The engine will be permanently damaged.

Checking and Filling Fuel

WARNING!

TO PREVENT SERIOUS

INJURY FROM FIRE:

Fill the fuel tank in a well-ventilated area

away from ignition sources. If the engine is

hot from use, shut the engine off and wait

for it to cool before adding fuel.

Do not smoke.

1. Clean the Fuel Cap and the area around it.

2. Unscrew and remove the Fuel Cap.

3. If needed, fill the Fuel Tank to about 1 inch

under the fill neck of the Fuel Tank with 87

octane or higher unleaded gasoline.

Note: Do not use gasoline containing more than

10% ethanol (E10). Do not use E85 ethanol.

Note: Do not use gasoline that has been stored in a

metal fuel container or a dirty fuel container. It can

cause particles to enter the carburetor, effecting

engine performance and/or causing damage.

4. Then replace the Fuel Cap.

5. Wipe up any spilled fuel and allow excess

to evaporate before starting engine. To

prevent FIRE, do not start the engine while

the smell of fuel hangs in the air.

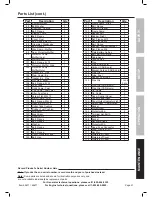

Summary of Contents for 69671

Page 1: ......