12

10.04

Wrap the end of the transition tube with one

layer of the felt tape provided and secure to

the bottom of the transition compartment with two of

the tie wraps provided. (Figure 27)

FIGURE 27 - SECURING TRANSITION TUBE FOR

CABLES ENTERING TOP END PLATE PORTS

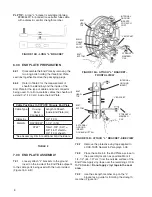

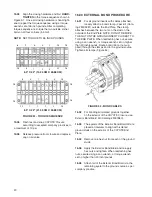

11.00 ROUTING AND STORING FIBER IN

THE TRANSITION COMPARTMENT

11.01

When routing fiber in the transition compart-

ment of either size closure for continuous

loop applications, cut the fibers to be spliced at the

midpoint of the loop. This allows for splicing in either

direction. Lay the fibers to be spliced directly through

the transition compartment exiting the opposite end.

These fibers will be routed to splice trays 1-4 of the

6.0" x 22" (15.24 cm x 55.88 cm) and trays 1-8 of

the 8.5" x 22" (21.59 cm x 55.88 cm) via transport

tubes. Wrap the continuous loop, and the fibers not

being spliced, until all fibers are stored in the transi-

tion compartment. For cut cables bring all fibers to be

spliced directly through the transition compartment

exiting the opposite end of the same corner

(Figure 28).

FIGURE 28 - ROUTE FIBERS IN TRANSITION

COMPARTMENT – 6.0" X 22" AND 8.5" X 22"

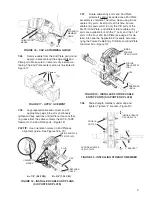

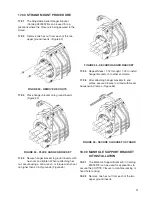

12.00 INSTALLING FIBERS INTO

TRANSPORT TUBES AND

SECURING TO TRANSITION

COMPARTMENT

12.01

Group fibers into bundles determined by how

many fibers will be inserted into each trans-

port tube. A maximum of six transport tubes can be

terminated per splice tray.

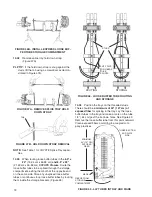

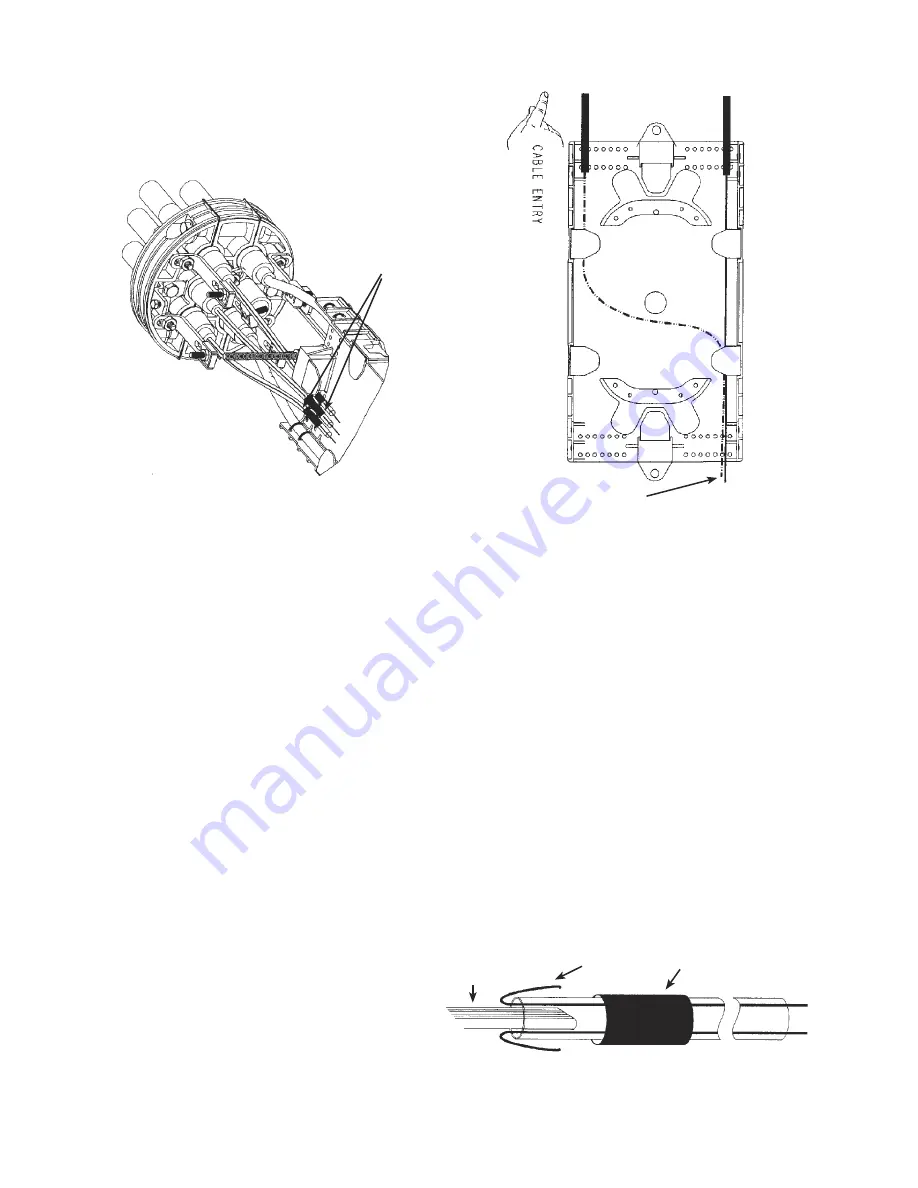

12.02

Push fibers through the transport tubes.

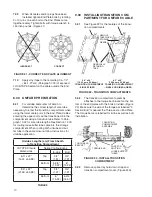

NOTE:

For ribbon fiber application, fiber guide wires

are provided. Suggested use is four ribbons per

tube. (Figure 29)

FIGURE 29 - GUIDE WIRES IN USE

RIBBON

FIBER

FELT

FIBER

GUIDE

WIRE

FELT

EXIT POINT FOR FIBERS

TO BE SPLICED

Summary of Contents for COYOTE 80805112

Page 23: ...23...