16

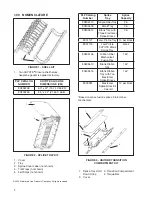

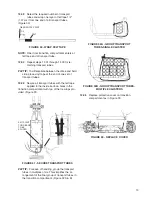

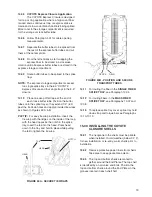

FIGURE 41 - ROUTING FIBERS IN THE

MASS FIBER SPLICE TRAY FOR MASS FUSION

13.08

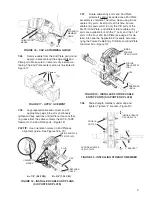

Splice fibers according to accepted company

practices. (Refer back to Figure 38)

PLP TIP:

If splice protectors loosely fit in the slots

of the splice block, wrap each protector with felt

tape to provide the desired fit

or

use a bead

of silicone caulk to secure the connectors and

place a strip of felt tape over the connectors and

silicone caulk.

13.09

Replace all tray retaining tabs.

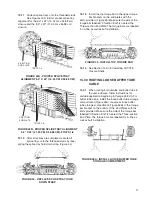

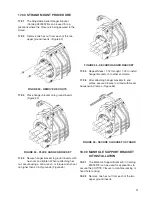

13.10

To replace tray cover, position pivotal arm on

plastic cover underneath the hinges on the

splice tray and snap into place. (Figure 42)

FIGURE 42 - REPLACE SPLICE TRAY COVER

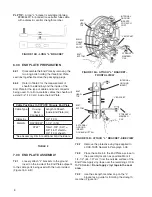

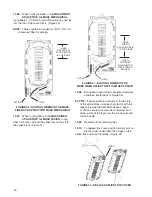

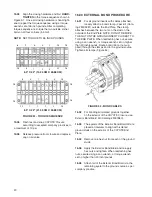

13.06

When routing the fiber in the

MASS FIBER

SPLICE TRAY for MASS MECHANICAL

,

route fibers 1-1/2 times around the splice tray and lay

into the top of the splice block. (Figure 40)

NOTE:

There should be a minimum of 50" (127 cm)

of exposed fiber for splicing.

FIGURE 40 - ROUTING FIBERS IN THE MASS

FIBER SPLICE TRAY FOR MASS MECHANICAL

13.07

When routing fibers in the

MASS FIBER

SPLICE TRAY for MASS FUSION

, route

fiber 1-3/4 times around the splice tray and lay into

the splice block. (Figure 41)

HINGE

MASS

MECHANICAL

SPLICE BLOCK–

8 POSITIONS

FIELD

OFFICE

FIELD

OFFICE

MASS

FUSION

SPLICE BLOCKS–

16 POSITIONS

(USE 12

POSITIONS

MAXIMUM FOR

MASS FUSION

SPLICES)

Summary of Contents for COYOTE 80805112

Page 23: ...23...