18

ROUTING STORING

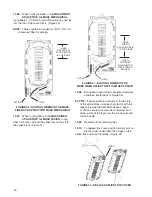

FIGURE 48 - LOOSE BUFFER TUBE ROUTING

AND STORAGE

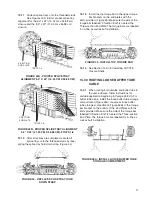

14.04

Position the trays on the threaded studs.

There should be

a minimum of 50" (127 cm) of

exposed fiber

for splicing in the tray. Lay the loose

buffer tubes in the tray and make a mark on the tube

1/4" (.64 cm) past the tie down holes. See Figure 49.

Remove the loose buffer tube from this point outward.

Clean exposed fibers according to accepted com-

pany practices.

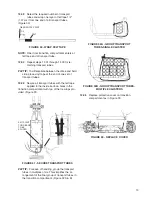

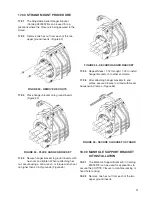

FIGURE 49 - LAY TUBES IN TRAY AND MARK

STUDS

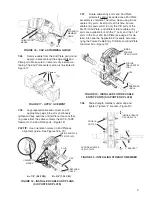

FIGURE 46B - INSTALL EXPRESS LOOSE BUF-

FER TUBE STORAGE COMPARTMENT

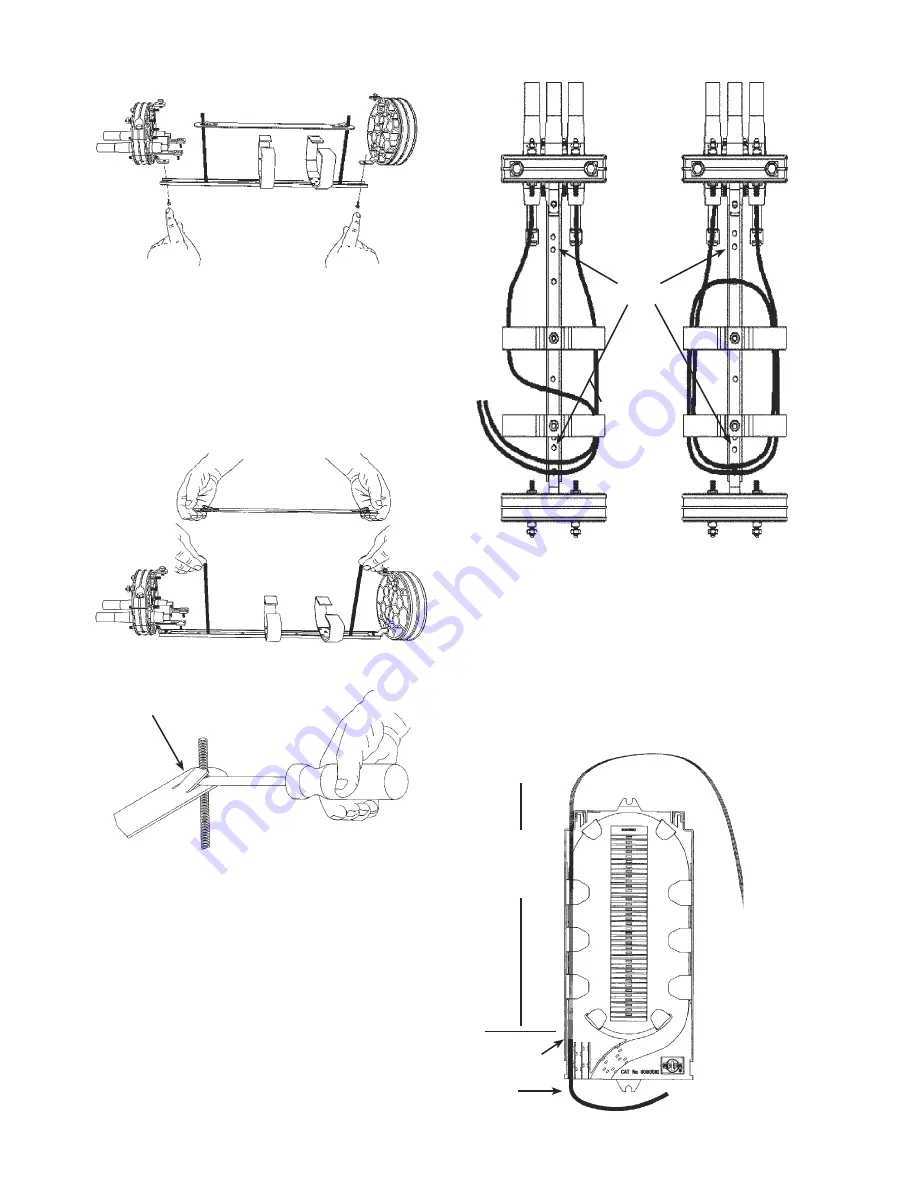

14.02

Remove splice tray hold down strap.

(Figure 47A)

PLP TIP:

If the hold down strap is snug against the

studs, lift the tab using a screwdriver as demon-

strated in Figure 47B.

FIGURE 47A - REMOVE SPLICE TRAY HOLD

DOWN STRAP

FIGURE 47B - HOLD DOWN STRAP REMOVAL

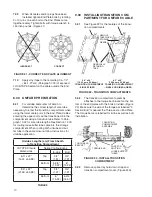

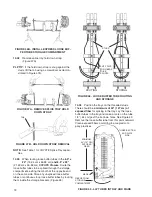

NOTE:

See Table 1 for COYOTE Splice Tray capaci-

ties.

14.03

When routing loose buffer tubes in the

6.0" x

22"

(15.24 cm x 55.88 cm)

and 8.5" x 22"

(21.59 cm x 55.88 cm)

COYOTE Closure

. Route the

loose buffer tubes to be spliced through the storage

compartment, exiting them both at the opposite end

on the same side. Store any unspliced loose buffer

tubes or continuous loop loose buffer tubes by routing

them inside the storage brackets. (Figure 48)

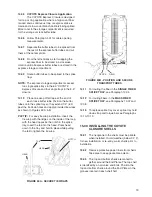

MARK

➔

THREE-SECTION

END PLATE

SIDE

FIBERS FROM

STORAGE

COMPARTMENT

MINIMUM

50" (127 CM)

EXPOSED

FIBER

TAB

EXIT POINT

FOR FIBERS

TO BE

SPLICED

Summary of Contents for COYOTE 80805112

Page 23: ...23...