8

Assembly Instructions, POWER RAIL

TM

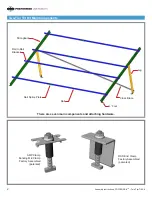

‒ Two-Tier Tilt Kit

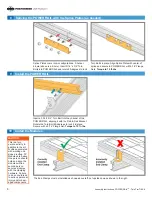

Splice Plates come in two configurations, 2-hole or

4-hole (above is a 4-hole). Insert 5/16” x 3/4” Turn

Bolts into POWER RAIL and rotate 90-degrees to lock

Turn Bolts in place. Align Splice Plate with center of

splice and secure to POWER RAIL with 5/16” Flange

Nuts.

Torque to 15 ft.-lbs.

8 Splicing the POWER RAIL with the Splice Plates (as needed)

Insert a 5/16”x 3/4” Turn Bolt into the channel of the

POWER RAIL, aligning it with the Rail-to-Rail Bracket.

Rotate the Turn Bolt 90-degrees to lock it in place.

Secure with a 5/16” Flange Nut.

Torque to 15 ft.-lbs.

9 Install the POWER RAIL

CAUTION

This is a two

person activity. In

addition to the dif

-

ficulties associated

with working on a

sloped rooftop, PV

Modules are heavy.

One person should

hold and align the

modules while a

second person

secures modules

with the clamping

hardware. Failure

to do so could lead

to serious personal

injury and/or dam

-

aged components.

10

Install the Modules

The End Clamps must be installed as shown above left, not upside down as shown to the right.