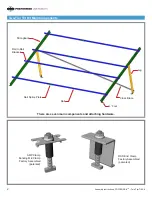

Assembly Instructions, POWER RAIL

TM

‒ Two-Tier Tilt Kit

1

POWER RAIL

TM

‒ Two-Tier Tilt Kit

About these instructions:

• The instructions do not include any

information on the selection or installa

-

tion of attaching hardware to be mount

-

ed to the roof substrate or concrete

foundation. For information on com

-

patible roof attaching hardware, see

our publication titled “POWER RAIL

TM

Design Guidelines”.

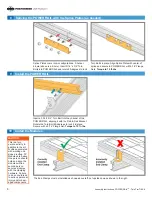

• Begin after all attaching hardware has

been installed and secured to the roof

substrate or concrete foundation.

• They are intended to be used by individ

-

uals with sufficient technical skills for the

task. Knowledge and use of hand tools,

measuring devices and torque values is

also required.

• Included, are various Notes, Cautions,

and Warnings that are intended to assist

in the assembly process and/or to draw

attention to the fact that certain assembly

steps may be dangerous and could cause

serious physical injury and/or damage to

components. Follow the procedures and

precautions in these instructions carefully.

For questions on a specific installation, please:

Contact us by Phone: 800-260-3792

Send an Email request: info@PLPSolar.com

WARNING

Follow the

procedures and

precautions in

these instructions

carefully.

Periodic Inspection

PLP recommends a periodic re-inspection to

check for any loose components or any corro

-

sion. If any loose components and any corrosion

is found, the affected components are required to

be replaced immediately, with the original mount

-

ing system manufacturer’s component parts.

Required Tools

o

3/4 inch wrench or socket for 1/2 inch

hardware

o

1/2 inch wrench or socket for 5/16 inch

hardware

o

Torque wrench

o

Ratchet wrench

o

Ratchet extension bar

o

Framing square

o

Tape measure