4

Assembly Instructions, POWER RAIL

TM

‒ Two-Tier Tilt Kit

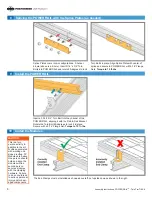

2 Measure and Mark the “L” Foot and the Leg Attachment Points on the Strongbacks

CAUTION

Span dimensions

are a design spec

-

ification. Consult

the design manual

to match these

dimensions to site

conditions. It’s

important to use

the unique span

dimension specific

to the install. Fail

-

ure to do so could

lead to excessive

deflection and/or

premature system

failure.

To ensure consistency and structural integrity, the

attachment points of the “L” Feet and Legs must be in

accordance with the above diagram and the “Spacing

Calculations” on page 3. Measure and mark each

Strongback to establish attachment points for the “L”

Foot and Leg.

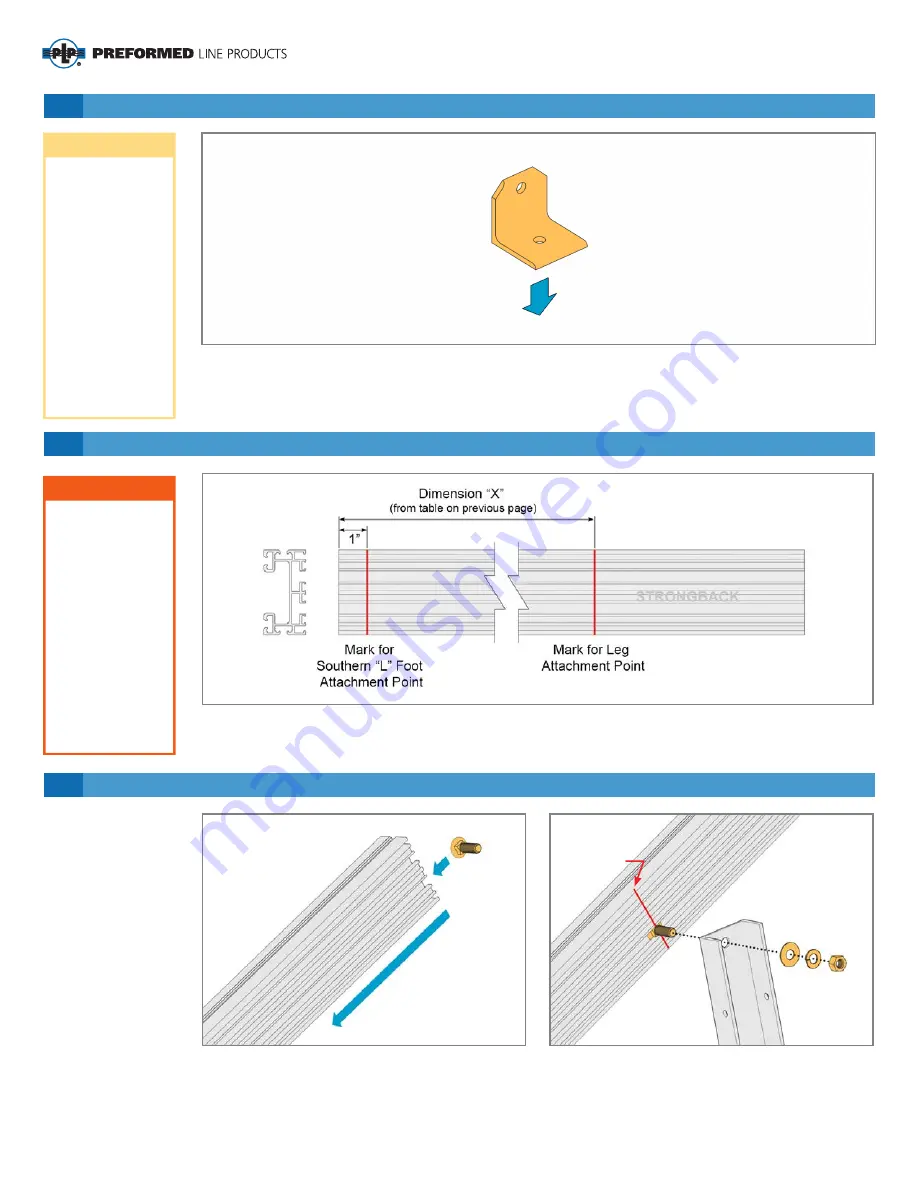

Insert a 1/2”-13 x 1-1/2” Carriage Bolt into channel of

Strongback and slide it down to the previously made

alignment mark. Install the Leg and secure with a 1/2”

Flat Washer, Lock Washer and Nut. Tool tighten for

now allowing the Leg to pivot/rotate as needed and

align to the “L” Foot.

3 Attach the Leg to the Strongback

Leg

Alignment

Mark

1 Install the “L” Feet

Secure the “L” foot to the site-specific anchoring

device such as the foundation, roof structural member,

or surface anchoring device per the device manufac

-

turers’ instructions. “Site specific anchoring device”

NOTE

“L” Feet can be

attached directly to

the roof substrate

with the proper

hardware. See

POWER RAIL

Design Guidelines

for more informa

-

tion.

Information on

appropriate

anchoring

hardware is

available on an

individual product

basis.

means an appropriate surface attachment for the

roof or substrate in which the Two-Tier Tilt Kit will be

installed.