Assembly Instructions, POWER RAIL

TM

‒ Two-Tier Tilt Kit

7

7

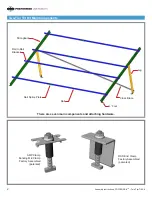

Install the Rail-to-Rail Brackets

For Rail-to-Rail Bracket positioning, measure and

mark their four locations along the Strongbacks.

Span and placement of the Rail-to-Rail brackets along

the Strongback is dependent on the module in use

and its clamping locations. If the module manufacturer

has provided specific clamping locations, use those

specifications; if none are specified by the manufac-

turer, use a factor of 20-percent of the module length

to determine the N-S positions of the Rail-to-Rail

Brackets. Measure and mark the Strongbacks.

Module Length

Module

Module Length

Module

20%

20%

20%

20%

Rail-to-Rail

Bracket

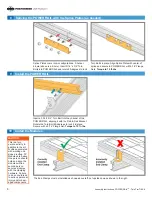

Insert a 5/16”-18 x 3/4” Turn Bolt into the channel of

the Strongback, aligning it to one of the previously

made alignment marks, and rotate 90-degrees to lock

the Turn Bolt in place. Secure the Rail-to-Rail Bracket

with a 5/16” Flange Nut.

Torque to 15 ft.-lbs.