11

14.00 UNDERGROUND INSTALLATION

14.01

The Closure should be installed between

the manhole racks.

14.02

COYOTE Closures are very light and will

float in a water-filled manhole. They must be

tied down.

NOTE: It is recommended that the PREFORMED

Manhole Support, Catalog No. 8003527, be

used to support and tie down the Closure.

15.00 AERIAL INSTALLATION

15.01

For aerial applications, use the Adjustable

Aerial Hanger Bracket Kit (Catalog No.

8003426).

15.02

Be sure all nuts and washers are in their

proper position. Tighten nuts securely.

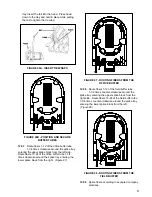

16.00 EXTERNAL BONDING

External bond methods will be described, but com-

pany practices should be followed.

16.01

If cable contains metallic components, all

cables must be bonded together. Remove

bolt from threaded inserts on outside of the End

Plate, install continuous length of bonding ribbon to

each threaded insert through bonding clips and

secure to End Plate with the removed bolts.

16.02

For manhole installations, extend a length of

bonding ribbon (not supplied) from one of the

threaded inserts bonding and grounding harness of

the manhole. Securely tighten all connections.

16.03

For direct buried installations, extend a

length of bonding ribbon (not supplied) from

one of the threaded inserts to a ground rod. Securely

tighten all connections.

16.04

For isolation of individual external grounding

connections, use the COYOTE EXTERNAL

ISOLATION TERMINAL KIT (Catalog No. 8003463 or

8003464). Refer to application procedure SP2891

for specific installation application.

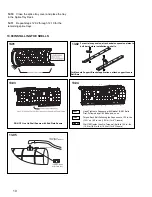

17.00 MAINTENANCE PROCEDURE

17.01

The COYOTE Closure is designed for

numerous re-entries. However, certain

precautions must be taken prior to reapplication.

17.02

Be sure to clean shells and End Plates

thoroughly to remove sand, dirt, and other

foreign substances.

17.03

Any bent studs or stripped nuts should be

replaced. Only use hardware supplied by

Preformed Line Products.

17.04

The shells should be lubricated prior to re-

application. A uniform thin layer is all that is

necessary. Only use lubrication supplied by Pre-

formed Line Products (Catalog No. 80801566).

17.05

Any shells that are bent, cracked or distorted

should not be used.

17.06

Prior to reinstallation, the neoprene on the

shells should be allowed to return to its

original state. Warming the shells speeds up the

process.