2

3

.

1

.

2

.

4

.

5

.

10

.

9

.

8

.

7

.

6

.

1.00 NOMENCLATURE (See Figures 1&2):

1.

Bolt Bars

2.

Shell Halves

3.

3/4" LOCK-TAPE™ Sealant

4.

End Plates

5.

LOCK-TAPE Sealant Strips

6.

Cap/Blank Cap (shell kit w/air flange only)

7.

Cable Mea-SURE™ Tape

8.

Aerial Hanging Brackets

9.

Bond Clamp

10. Emery Cloth

FIGURE 1 - COYOTE CLOSURE

COMPONENTS (TYPICAL)

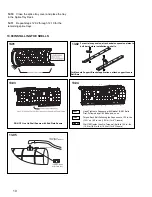

1. “L” Brackets

2. Top Run Torque Bar

3. Buffer Tube Storage and Splice Tray Rack

4. Splice Tray Kit with Clear Cover, Felt Strips, and

Tie Wraps(1)

NOTES:

1. Splice Trays sold separately.

FIGURE 2 - COYOTE HI-COUNT CLOSURE

BUFFER TUBE STORAGE ASSEMBLY AND

RELATED COMPONENTS

1.01

The COYOTE

®

HI-Count Closure contains

everything needed for installation except

hand tools, vinyl tape, filled cable cleaning fluid,

and C-Cement.

1.02

Tools Needed:

— Splicer’s scissors

— Splicer’s knife

— Tabbing shears

— Common screwdriver

— 1/2" deep well socket*

— 3/8" nutdriver or socket

— Needlenose pliers

— Buffer tube removal tool and/or slitter

— Sidecutters

— Torque Wrench (inch pound readings)*

— Power End Plate Cutter*

*Available from Preformed Line Products

2.00

DESCRIPTION

2.01

For Safety Considerations, refer to section

18.00 of this procedure.

2.02

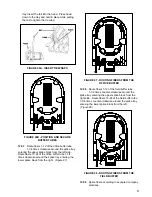

The COYOTE Hi-Count Closure is specifi-

cally designed for organizing and protecting

the buffer tubes (loose tubes) and individual fiber

splices of high count (up to 432 fibers), loose tube

optic cables.

2.03

The unique buffer tube management system

and inclined, snap-in splice tray arrangement

combine to provide space for splicing up to 432

individual fibers in a compact 9.5" X 28" (241.3 mm x

711.2 mm) Closure. The COYOTE Hi-Count Closure

will accommodate up to 18 individual 24 count

Splice Trays.

2.04

The COYOTE Hi-Count Closure End Plates

have cable capacity for six cables with

L-Bracket supports (Figure 3).

©2001 Preformed Line Products Company. All rights reserved.