3

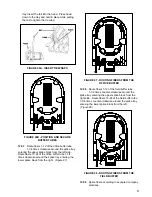

FIGURE 3 - END PLATE CAPACITY

(VIEW FROM INSIDE END PLATE)

NOTE:

An additional 3.0" (76.2 mm) of space is

available on each seam of the COYOTE

Hi-Count Closure. However provisions for

securing the L-Brackets are only provided for

six entries as shown in Figure 3.

3.00

DETERMINING BLADE SIZE AND

LOCK-TAPE SEALANT REQUIRE-

MENTS

3.01

The CABLE Mea-SURE Tape is used to de-

termine the correct Power End Plate Cutter

blade size and the required layers of LOCK-TAPE

Sealant.

3.02

To use CABLE MeaSURE Tape:

— Wrap it around the cable tightly. (Figure 4)

— The index line will point to a letter and

number.

— The letter indicates the correct blade size.

— The number indicates the correct number

of layers of half-lapped LOCK-TAPE

Sealant. (Figure 4)

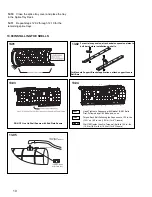

FIGURE 4 - WRAP CABLE MEA-SURE TAPE

AROUND CABLE

NOTE:

If the index line falls on a line between two

numbers, always use the number to the right of

the line. (Figure 5)

FIGURE 5 - SKETCH OF CABLE MEA-SURE TAPE

CAUTION: Cable may vary in diameter from place to

place along its length, so be sure to measure

each cable at the area where the End Plate is

to be placed.

4.00

END PLATE PREPARATION -

CUTTER SET-UP

4.01

When using blades A-D, install the blade

directly into the chuck. For blades E-DD, first

install blade into drill adapter.

4.02

Secure blade or adaptor into drill chuck.

Tighten drill chuck in all three locations.

CAUTION: To prevent blades from coming in

contact with base of Power End Plate Cutter,

insure that blade or adapter is inserted as far

into the drill chuck as possible.

4.03

Insert stop-posts in tapped holes in base of

cutter corresponding to the 9.5" (241.3 mm)

End Plate diameter and hand tighten firmly.

(Figure 6)

FIGURE 6 - PUT STOP POSTS INTO CUTTER

5.00

END PLATE PREPARATION -

DRILLING

5.01

Locate the designated drill marks on the End

Plate (highlighted in yellow). These marks

should face up when placing End Plate in the Power

End Plate Cutter. (Figure 7)

9.5" (241.3 mm) DLX

THREE-SECTION

END PLATE

3 ENTRIES

PER SEAM

MAX. DIA.

1.1"

Use D blade and

one half-lap of

LOCK-TAPE

TM

Sealant.

Use D blade and

one half-lap of

LOCK-TAPE

TM

Sealant.

Use M blade and

two half-laps of

LOCK-TAPE

TM

Sealant.

Use O blade and

two half-laps of

LOCK-TAPE

TM

Sealant.

The shaded area = two half laps.

The clear area = one half lap.