5

FIGURE 11 - END PLATE WITH HOLES DRILLED

5.08

Remove the End Plate from the cutter and

disassemble End Plates by removing both bolts.

6.00 END PLATE PREPARATION -

LOCK-TAPE SEALANT

APPLICATION

6.01

Remove sharp edges on plastic and foam in

area of opening with emery cloth (provided).

(Figure 12)

SCUFF LIGHTLY.

DO NOT REMOVE TOO MUCH MATERIAL

FIGURE 12 - SCUFFING CABLE OPENINGS

PLP TIP:

This simple operation will help prevent

catching the LOCK-TAPE Sealant when drawing

the End Plates together. ONLY USE EMERY

CLOTH PROVIDED FOR THIS PROCEDURE.

6.02

Apply a thin coat of C-Cement to each inside

surface of the End Plate sections.

6.03

When the C-Cement becomes tacky, remove

protective backing from a strip of LOCK-

TAPE Sealant.

PLP TIP:

Use removed backing from a LOCK-

TAPE Sealant strip to dry and remove excess C-

Cement applied to End Plate. (Figure 13)

FIGURE 13 - C-CEMENT ON END PLATE

6.04

Without stretching, apply LOCK-TAPE

Sealant over prepared surface of the End

Plates, following the contour of the cable holes.

Allow approximately 3/4" (19.05 mm) of LOCK-TAPE

Sealant to extend beyond each end of the End Plate.

This will serve as a tighting indicator during the End

Plate assembly.

6.05

Square cut the tape away from the bolt

holes. (The area just beyond the metal

insert.) (Figure 14)

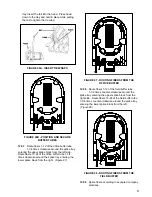

FIGURE 14 - SQUARE CUT BOLT HOLES

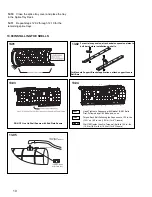

7.00

CABLE PREPARATION - APPLYING

LOCK-TAPE SEALANT TO

CABLES FOR FIELD-DRILLED END

PLATES

7.01

Measure and mark the cables at 80" (2.03 m)

for the opening of the sheath.

7.02

Remove the cable sheath to open the

appropriate amount of cable. Remove any

other coverings to expose the buffer tubes in the

center of the cable.

7.03

The cable must now be marked for the

installation of the LOCK-TAPE Sealant.