6

— For cables with metallic components, the cable

must be marked in two places. Measuring from the

opened cable end, make one mark at 1.5" (38.10

mm) and the second at 5.5" (139.7 mm).

— For cables without metallic components, only one

mark is required. Again measuring from the opened

cable end, make one mark at 4" (101.6 mm).

Now that the cable is marked, take the emery cloth

provided and scuff the cable between the marks for

cables with metallic components and from the open

end of the cable to the mark for dielectric cables.

Always scuff around the cable, never scuff length-

wise.

7.04

Coat the scuffed area of the cable with C-

Cement and allow to dry to tacky base.

7.05

Apply required number of half lapped layers

of 3/4" (19.05 mm) LOCK-TAPE Sealant

around the cable in the area coated with C-Cement.

Stretch tape while applying. (Figure 15)

PLP TIP:

Stretch tape enough to reduce its width

to 1/2" (12.7 mm). Figure 16 shows the com-

pleted application of one half-lapped layer of

LOCK-TAPE Sealant.

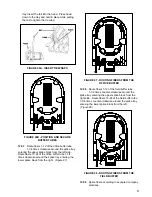

FIGURE 15 - APPLYING LOCK-TAPE SEALANT

FIGURE 16 - COMPLETED LOCK-TAPE SEALANT

APPLICATION

8.00

END PLATE ASSEMBLY

8.01

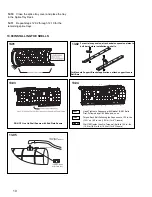

Using the hex bolts provided, fasten the “L”

bracket and retaining clip to the End Plate.

8.02

Before installing prepared cables into End

Plate halves, apply 1/4" (6.35 mm) wide bead

of C-Cement adjacent to the drilled hole. (Figure 17)

FIGURE 17 - BRUSH C-CEMENT OVER LOCK-

TAPE SEALANT

NOTE: If cables being placed in End Plate require

bonding and/or grounding, review Section 9.00

before installing End Plate.

8.03

Position prepared cables into lower End

Plate section, allowing 1/2" (12.7 mm) of the

LOCK-TAPE Sealant to extend beyond the inside of

the End Plate. THIS IS A CRITICAL MEASURE-

MENT.

8.04

For cables containing non-metallic strength

members, insert strength members into

retainer clip and tighten. Cut off excess strength

member.

8.05

Where applications dictate, position prepared

cables into upper End Plate seam per step

8.03 and insert End Plate bolts.

8.06

Using a socket and ratchet, tighten each bolt

evenly in rotation 2 to 3 turns at a time.

CAUTION: Do not use power tools for this operation.

8.07

While tightening, the excess LOCK-TAPE

Sealant extending from the End Plate section

will fold back. When the LOCK-TAPE Sealant stops

moving (folds back), the bolts are sufficiently tight.

(Figure 18)

FIGURE 18 - TAPE FOLDING BACK

CAUTION: DO NOT OVER TIGHTEN!