7

8.08

Trim excess LOCK-TAPE Sealant to within

1/8" (3.18 mm) of the End Plate. DO NOT

STRETCH TAPE DURING TRIMMING PROCESS.

9.00

BONDING AND/OR GROUNDING

CABLES WITH METALLIC COMPO-

NENTS

NOTE:

Installation of bonding and grounding

components may be easier if installed prior to

placing cables into End Plate.

9.01

If cable contains a metallic shield, install

shield connector and/or bonding assembly per

company instructions. A shield connector is available

separately from PLP under Catalog No. 80803989.

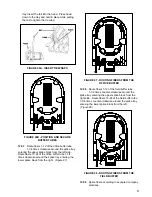

FIGURE 19 -BONDING ASSEMBLY

9.02

After the bond connector is installed on the

cable and the cable placed in the End Plate

next to the appropriate “L” bracket, attach the bond

connector to the “L” bracket through the slot pro-

vided.

9.03

If cable contains a strength member, insert

the strength member into the retainer clip

and tighten. Cut off excess strength member.

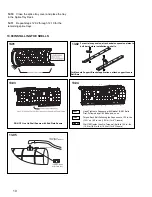

10.00 INSTALL ORGANIZER ASSEMBLY

10.01

Remove the torque bar attachment bolt from

the End Plate and secure the Buffer Tube

Storage and Splice Tray Rack Torque Bar to the End

Plate. (Figure 20)

FIGURE 20 - BUFFER TUBE STORAGE AND

SPLICE TRAY RACK ASSEMBLY SECURED TO

END PLATES

11.00 ROUTE BUFFER TUBES TO

SPLICE TRAYS

11.01

Route buffer tubes as follows:

— Buffer tubes for the back nine splice trays are to

be routed beneath the Splice Tray Rack Assembly

through the buffer tube storage clips as shown in

Figure 21.

— Buffer tubes for the front nine splice trays are to

be routed above the Splice Tray Rack Assembly

through the upper buffer tube storage clips as shown

in Figure 22.

FIGURE 21 - ROUTING OF BUFFER TUBES FOR

BACK SPLICE TRAYS