8

FIGURE 22 - ROUTING OF BUFFER TUBES FOR

FRONT SPLICE TRAYS

12.00 SECURING BUFFER TUBES AND

ROUTING FIBERS ON SPLICE TRAYS

12.01

The trays to be used in the COYOTE Hi-

Count Closure are single fiber trays designed

for single fusion heat shrink protected splice applica-

tions. These trays can accommodate up to 24 single

fusion heat shrink protected splices. (Figure 23)

FIGURE 23 - COYOTE HI-COUNT SPLICE TRAY

12.02

Open cover of splice tray. Note that the cover

is hinged on the right side and has two

locking points on the left-hand side. (Figure 24)

FIGURE 24 - REMOVE SPLICE TRAY COVER

12.03

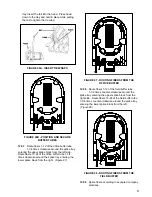

Position the back splice tray on the Splice

Tray Rack and route the buffer tubes into the

LEFT corner of the splice tray. Mark the buffer tubes

just beyond the tie down holes. (Figure 25)

FIGURE 25 - MARK THE BUFFER TUBES

12.04

Remove the buffer tube to the mark and

thoroughly clean the fibers per standard

company practices.

12.05

Apply a wrap of blue felt over the buffer tube

at the end where they will be tied down.

12.06

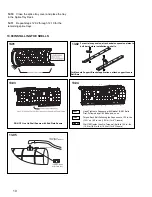

Position the buffer tubes onto the splice tray

so that they extend 1/4" (6.35 mm) past the

tie down holes and apply provided tie wraps as

shown in Figure 26 A & B.

PLP TIP:

For easy tie wrap installation, insert the

tie wrap with the ridges on the inside of the loop,

with the head opposite the notch in the splice