Compressor

control

13

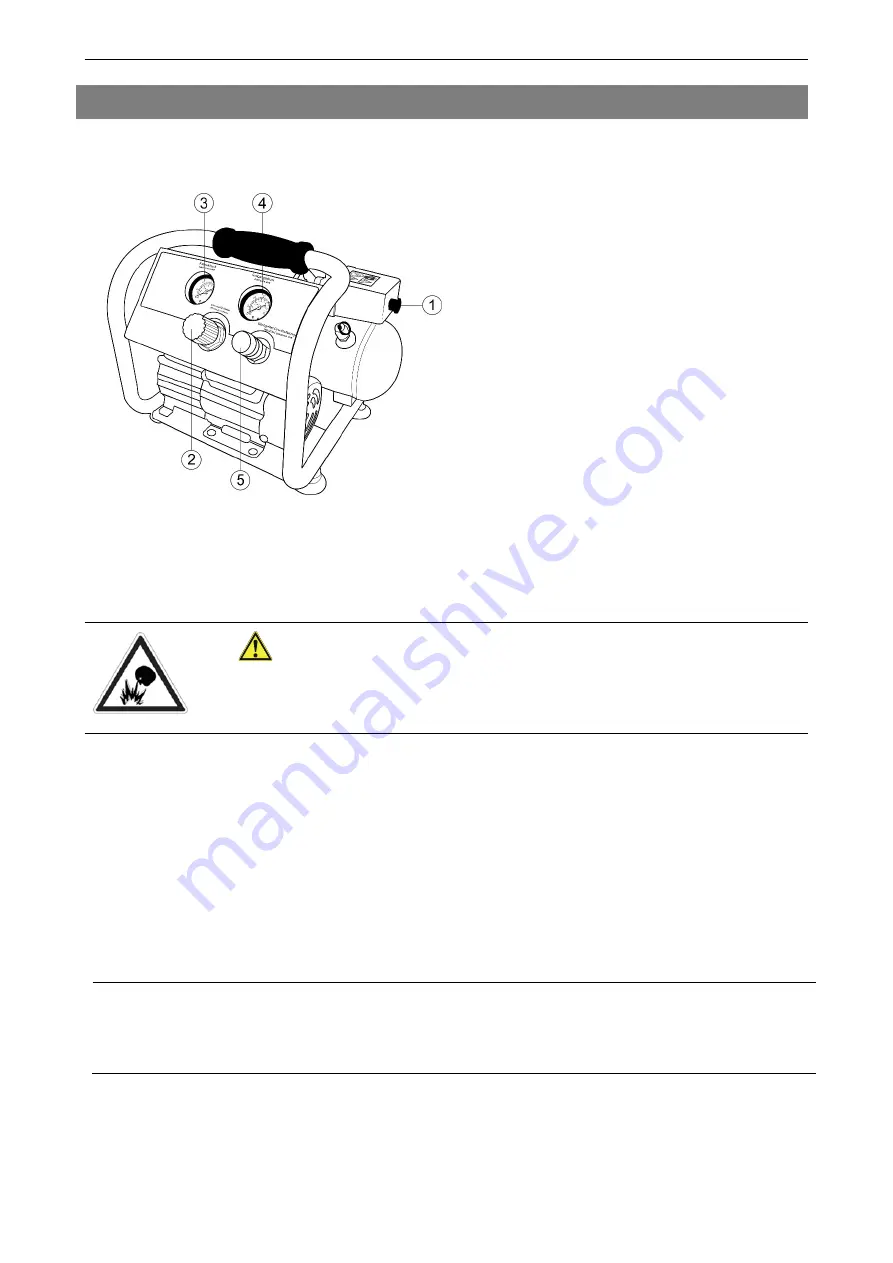

Compressor control

For compressor control, proceed as follows:

Prepare the compressor as described above, starting from page 10.

Switch on pressure reducer (2) by turning it counterclockwise.

Define allowable operating pressure of your edge device (pneumatic staple gun, painting gun, pneumatic

device for nailing, etc.)

Connect pressure hose of edge device to the union nipple (5).

Raise button (1) of pressure relay to start the compressor.

Wait until manometer (3) will not show the maximum operating pressure of appropriate compressor. Set

the allowable operating pressure of your edge device on pressure reducer (2).

o

Turn clockwise increases pressure.

o

Turn counterclockwise lowers pressure.

Turn of reducer on 90° changes operating pressure on about 0.5 bar

Operating pressure of edge device is reflected on the manometer (4).

The compressor starts automatically again as soon as pressure in the receiver falls after relief to starting

pressure (6-7 bar). This process is controlled automatically by pressure relay.

ATTENTION!

In case of overload the compressor can be damaged.

Do not overload the compressor: Do not exceed the ratio of operating time and downtime! See the technical

specifications, starting from page 7.

WARNING

Explosion risk by excess of the maximum allowable operating pressure.

Define characteristics of your edge device before compressor connecting.

Summary of Contents for AIRSTAR 45

Page 24: ...Notizen 24 Notizen ...

Page 25: ...Index 25 ...

Page 26: ...Original instructions of Compressor AIRSTAR 45 ...

Page 49: ...Notes 24 Notes ...

Page 50: ...Notice originale Compresseur AIRSTAR 45 ...

Page 72: ...Notes 23 Notes ...

Page 73: ...Notes 24 Notes ...

Page 74: ...Manual original Compresor AIRSTAR 45 ...

Page 96: ...Notas 23 Notas ...