ANTI-TIP BRACKET INSTALLATION

NOTICE: Parts supplied are for wood, concrete or ceramic tile floors. The plastic anchors are for mounting to concrete or

ceramic floors or walls. Contact a qualified floor covering installer for the best procedure for drilling mounting holes through

your type of floor covering.

WARNING

A child or adult can tip the range and be

killed. Install the anti-tip device to the

floor or the wall of the structure.

Engage the range to the anti-tip device

that is fastened to the wall or the floor.

Re-engage the anti-tip device if the

range is moved.

The anti-tip bracket is installed to prevent the range from tipping

forward as the result of excessive downward pressure on the

open end of the oven door. All ranges are required to have an

approved anti-tip bracket installed. The anti-tip bracket is

packed in the oven section of the range. If you did not receive an

anti-tip bracket with you purchase, call 1-800-858-5844.

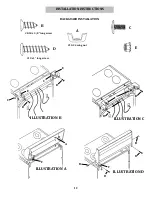

STEP 1

It is necessary to determine the final location of the range be-

fore you can locate the anti-tip bracket. If the range is going to

be located between cabinets, place the bracket so that Edge A

sits flat against the rear wall. Edge B should just touch the side

of the cabinet sitting to the right side of the range.

If there are no adjacent cabinets, align Edge B of the bracket

with the edge of the range side. After the bracket has been

placed mark the hole locations with a marker.

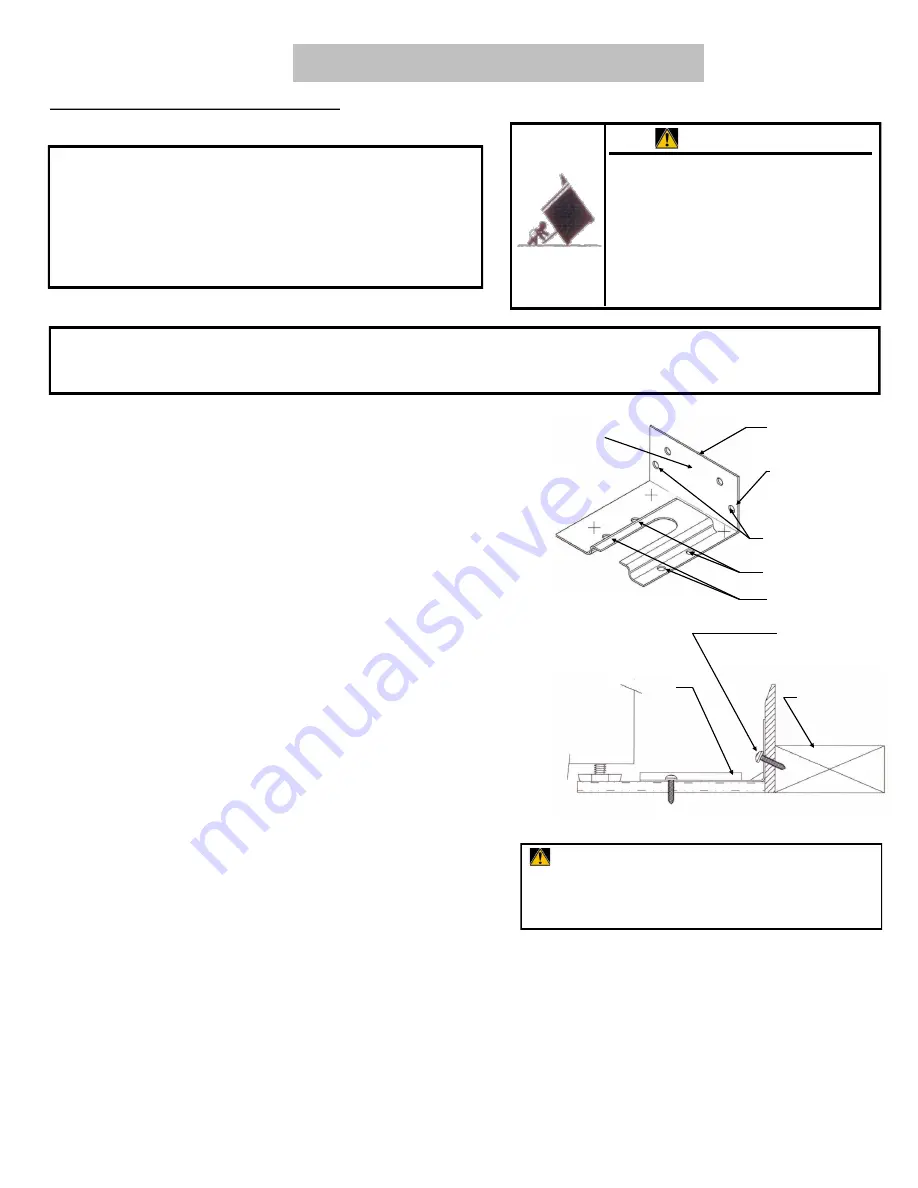

STEP 2

The anti-tip bracket can be attached to the floor or the wall. For

wall mount application use Location C. When using location C,

the screws must penetrate the wall sill plate located within the

wall. For floor mount application use Location D or E. One

screw on each side of the bracket is sufficient.

STEP 3

To mount anchor bracket to concrete or ceramic floor, use a

drill with a 3/16”masonry bit to drill the two holes. Tap plastic

anchor into mounting holes in floor with hammer. Line up

holes in anti-tip bracket to holes in floor. Use the two screws

provided to fasten anti-tip bracket to floor.

Edge A

Edge B

Location C

Location D

Screw must

penetrate solid

wood.

Wall Sill Plate

Location E

STEP 4

Unscrew the rear leg levelers approximately 1/2” so that the

rear leg levelers will slide in under the anti-tip bracket. Slide

range into the final position after completing the gas and elec-

trical connections to the range.

INSTALLATION INSTRUCTIONS

Anti-Tip Bracket

Anti-Tip Bracket

WARNING: IF RANGE IS EVER MOVED TO

A DIFFERENT LOCATION, THE ANTI-TIP

BRACKET MUST ALSO BE MOVED AND

INSTALLED WITH THE RANGE.

NOTE: The bracket should

engage the right rear leg

leveler.

15