35

Packaged and Split Rooftop Ventilator

© 2021 Mitsubishi Electric US, Inc.

Premi

Sys

Start-Up Components

CAUTION

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.), consult

manufacturer to determine if the unit can operate

safely at the new conditions.

Supply Fan (Plenum Type)

The unit contains one or two plenum supply fans

located on the end of the unit opposite the outdoor air

intake and may optionally have a relief air blower which

is referred to as an exhaust blower in this document.

Efficient fan performance can be maintained by having

the correct offset.

Refer to the respective Installation, Operation and

Maintenance Manual shipped with this unit for additional

start-up and maintenance information regarding the

plenum fan.

Fan

The fan should be checked for free rotation. If any

binding occurs, check for concealed damage and

foreign objects in the fan housing.

Inlet

Cone

Wheel

Offset

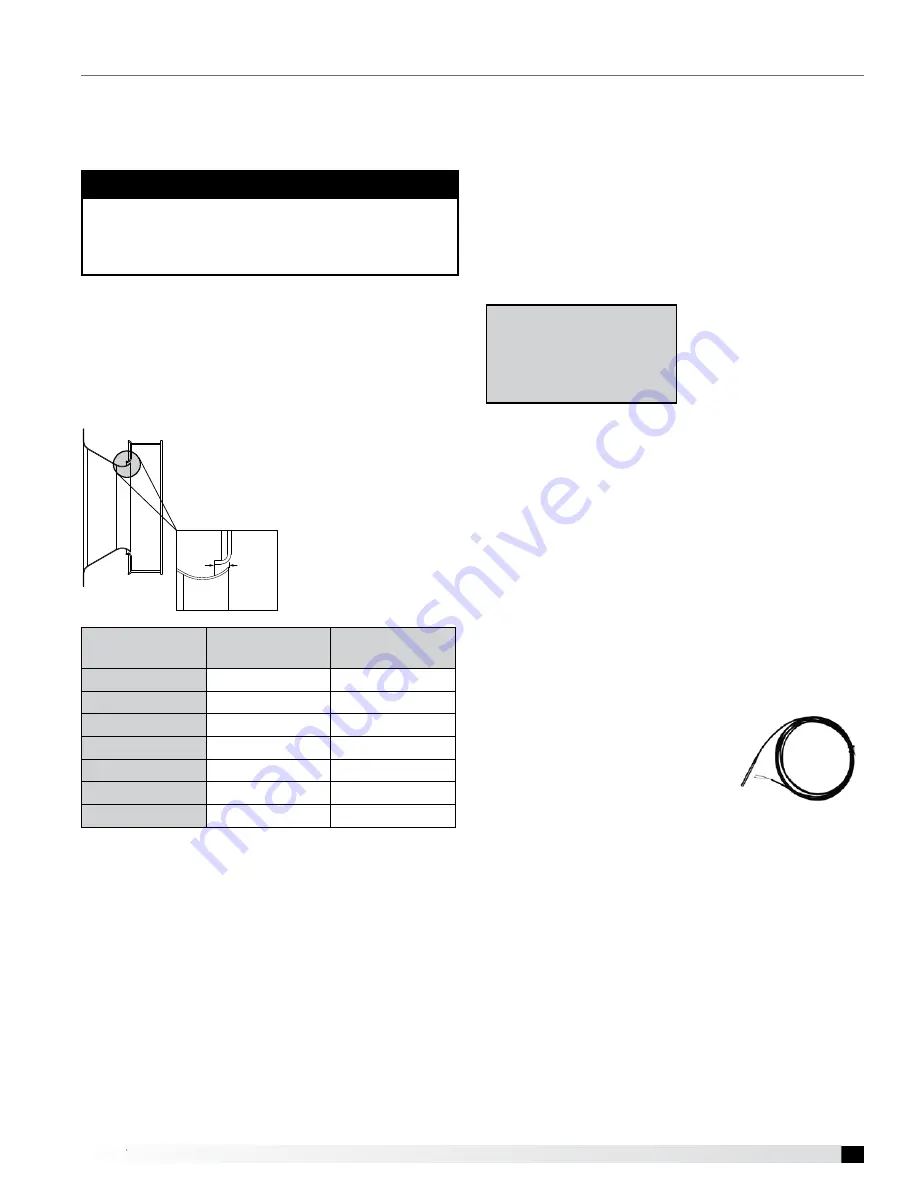

Offset:

Proper offset, or overlap, is

adjusted by loosening the wheel hub

from the shaft and moving the wheel

to the desired position along the shaft.

The transition between the inlet cone

and the wheel should

be as shown; there is

a smooth feel to the

profile when moving one

component to the other.

Fan Size

Offset

(inches)

Tolerance

(inches)

ER35C

5/32

± 1/32

ER45C

3/16

± 1/32

ER50C

13/64

± 1/32

ER56C

1/4

± 1/32

PDL-355

5/32

± 1/32

PRM-450

3/16

± 1/32

PRM-560

15/64

± 1/32

Supply/Exhaust Fan

The optional exhaust fan is a direct-drive plenum type.

Fan speed is controlled by a VFD which, in turn, is

controlled by the microprocessor controller or by an

external signal. Motor speed will be set on the VFD

during the unit Test and Balance, but after that, the

VFD will not normally be changed. Always check the

motor amperage rating shown on the motor nameplate

when changing the fan RPM. All access doors must be

installed except the control center door.

Vibration

Excessive vibration may

be experienced during

initial start-up. Left

unchecked, excessive

vibration can cause a

multitude of problems,

including structural and/

or component failure. The most common sources of

vibration are listed.

Many of these conditions can be discovered by careful

observation. Refer to the Troubleshooting section of

this manual for corrective actions. If observation cannot

locate the source of vibration, a qualified technician

using vibration analysis equipment should be consulted.

Generally, fan vibration and noise is transmitted to other

parts of the building by the ductwork. To eliminate this

undesirable effect, the use of flexible connectors is

recommended.

Discharge Air Temperature Sensor

Units are supplied with a Discharge Air Temperature

Sensor that is to be field-installed prior to unit start-

up. The sensor is to be installed

at least three duct diameters

downstream of the heat

exchanger. The sensor must

be connected directly to the

microprocessor controller. All

other sensors and low voltage

devices are to be connected to

the low voltage terminal strip in

the control center. The discharge air sensor is shipped

loose and can be found in the unit’s control center.

See the unit-specific wiring diagram for connection

locations.

Vibration Causes

Off axis or loose components

Drive component unbalance

Poor inlet / outlet conditions

Foundation stiffness

Typical Discharge Air

Temperature Sensor

Fan Wheel Rotation Direction

Check for proper wheel rotation by momentarily

energizing the fan. Rotation is determined by viewing

the wheel from the drive side and should match the

rotation decal affixed to the fan housing.

If the wheel is rotating the wrong way, direction can be

reversed by interchanging any two of the three electrical

leads. Check for unusual noise, vibration or overheating

of the bearings. Refer to the Troubleshooting portion of

this manual if a problem develops.