Page

9

of

12

8

Malfunction

The ExitOxy is designed as a quality and a trustworthy product. It can however, not be ruled out that the ExitOxy can get

defect. When this happens, a malfunction in the operational process of the machine is created. In that case the machine

will let the user know.

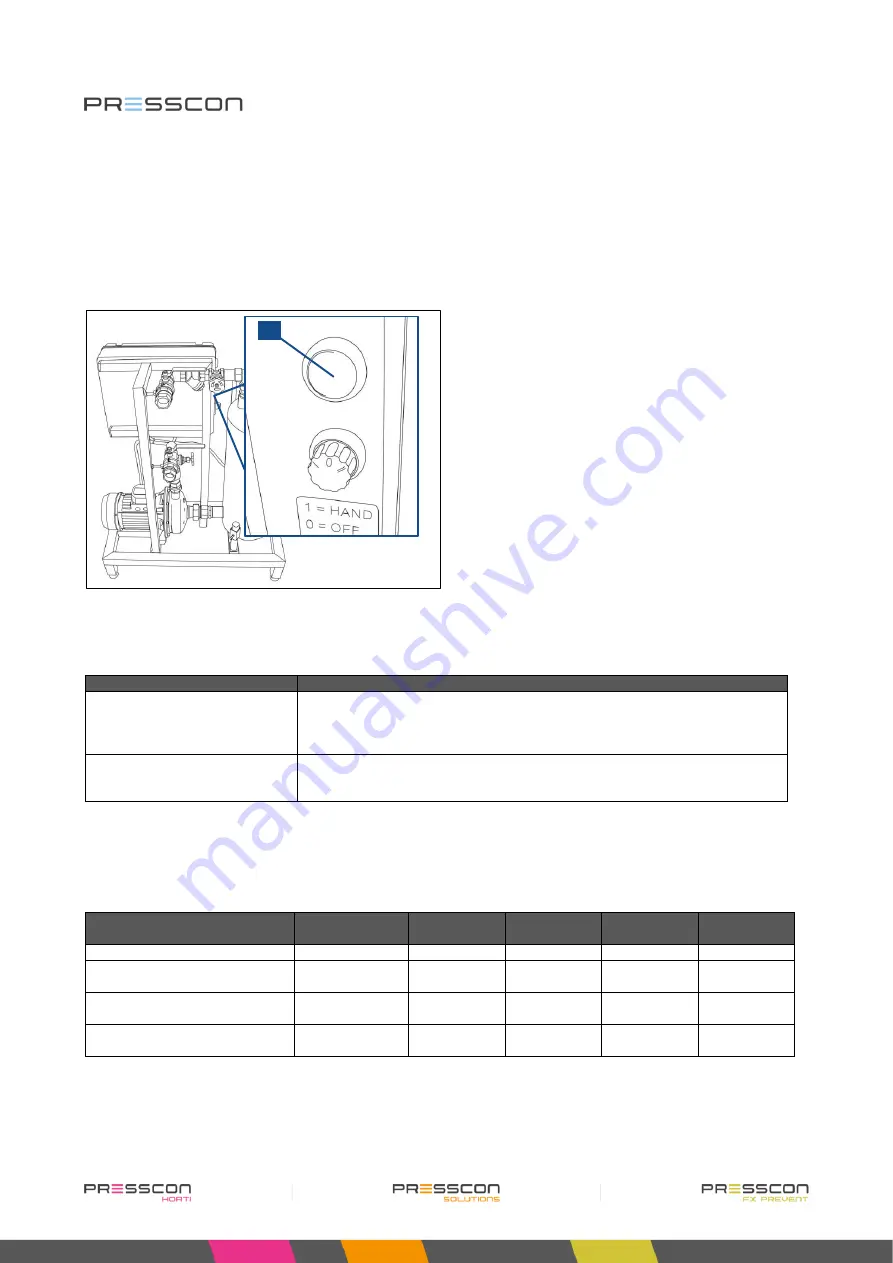

On the side of the switch cabinet is a red push-button (Figure 8. No. 1). When a malfunction occurs, the light behind the

push-button will start burning. This indicates a malfunction in the machine. By pushing the button, it can be attempted to

reset the malfunction. If the cause of the malfunction is fixed, the light after the button will turn off. If the cause isn’t fixed,

the lamp will keep burning and the cause will have to be fixed manually.

1.

Figure 8. Reset button

If there is a malfunction of the ExitOxy system then there may be the following issues.

Malfunction

Description

Pump thermally inoperative

The thermal protection of the water pump is addressed because the power

usage of the pump has been too high. Open the switch panel of the ExitOxy

and reset the thermal protection (Figure 5. No. 4). Research then the cause of

the high power usage of the pump.

Water level minimal

The water in the degasser tank has been too low because the water has been

sucked out too fast or is supplied to slowly. Check the dirt trap and the tap of

the supply line. Check the pump and the tap in the drain.

9

Maintenance

To ensure a proper working of the ExitOxy the owner must provide the system of its essential maintenance. A part of the

maintenance can be performed by the owner or his/hers technical staff. Other annual maintenance has to be performed

by a service mechanic. See table hereunder.

Activity

Conducted by

Weekly

Monthly

Annually

Every 2

years

Visual inspection

Owner

X

Cleaning the dirt trap

Service

mechanic

X

Cleaning measurement pins

Service

mechanic

X

Check the pump

Service

mechanic

X