Page 10 of 18

7. Test

Each PRESSCON produced vacuum-overpressure safety valve and vacuum safety valve is adjusted and

tested according to the regulations. Every vacuum-overpressure safety valve or vacuum safety valve is

provided with a unique serial number. The serial number is also mentioned on the test certificate. The test

certificate is added to the manual.

8. Maintenance

Every vacuum-overpressure safety valve and vacuum safety valve has to be checked yearly to guarantee a

correct operation. It is advised to let the vacuum-overpressure safety valve and the vacuum safety valve be

checked once a year and revised once every two years. The vacuum-overpressure safety valve can be

revised on the site by a mechanic of PRESSCON or an instructed technician. The vacuum safety valve can

only be revised in the factory of PRESSCON. There is an exchange program available with revised vacuum

safety valves in stock.

8.1 Maintenance for vacuum-overpressure safety valves

8.1.1 Annual check-up of the vacuum-overpressure safety valve

To check if the vacuum-overpressure safety valve is working satisfactorily, the annual inspection should be

performed according to the following work instruction.

1. Start by checking the pressure of the nitrogen blanket. This can be seen on the display of the

nitrogen generator.

2. Then climb the buffer tank and check whether the safety device is blowing or not. The type plate of

the safety valve indicates the operating pressure and the maximum pressure. Decide on the basis of

this information if the safety valve should be blowing off or if this should be closed.

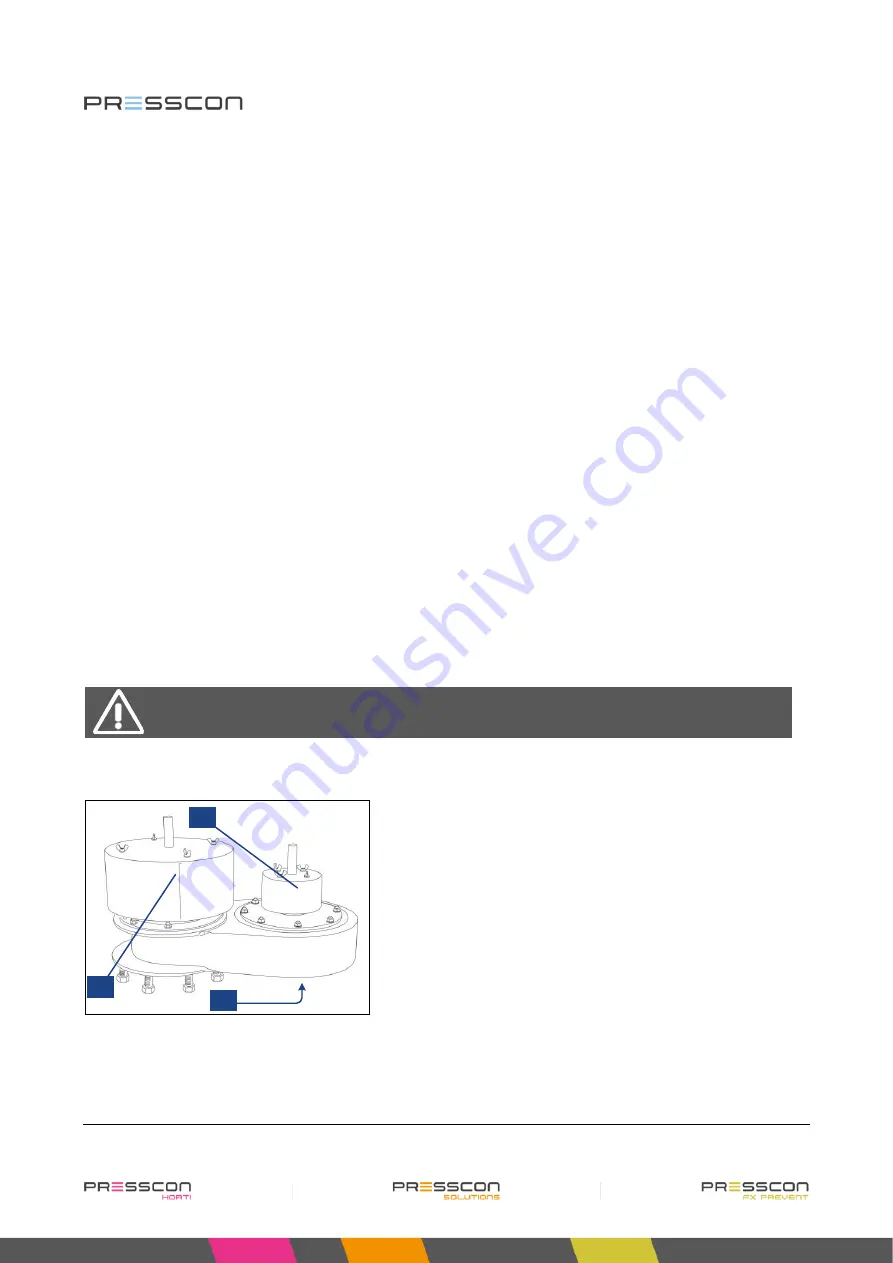

Caution! When opening the vacuum overpressure safety device, steam is released with

a temperature of 90°C. It is recommended to wear protective gloves and additional

protective clothing.

2.

1.

3.

Figure 3. Vacuum-overpressure safety valve

Summary of Contents for FX PREVENT

Page 2: ...Page 2 of 18...