24

SeCTION 3

OPeRATION

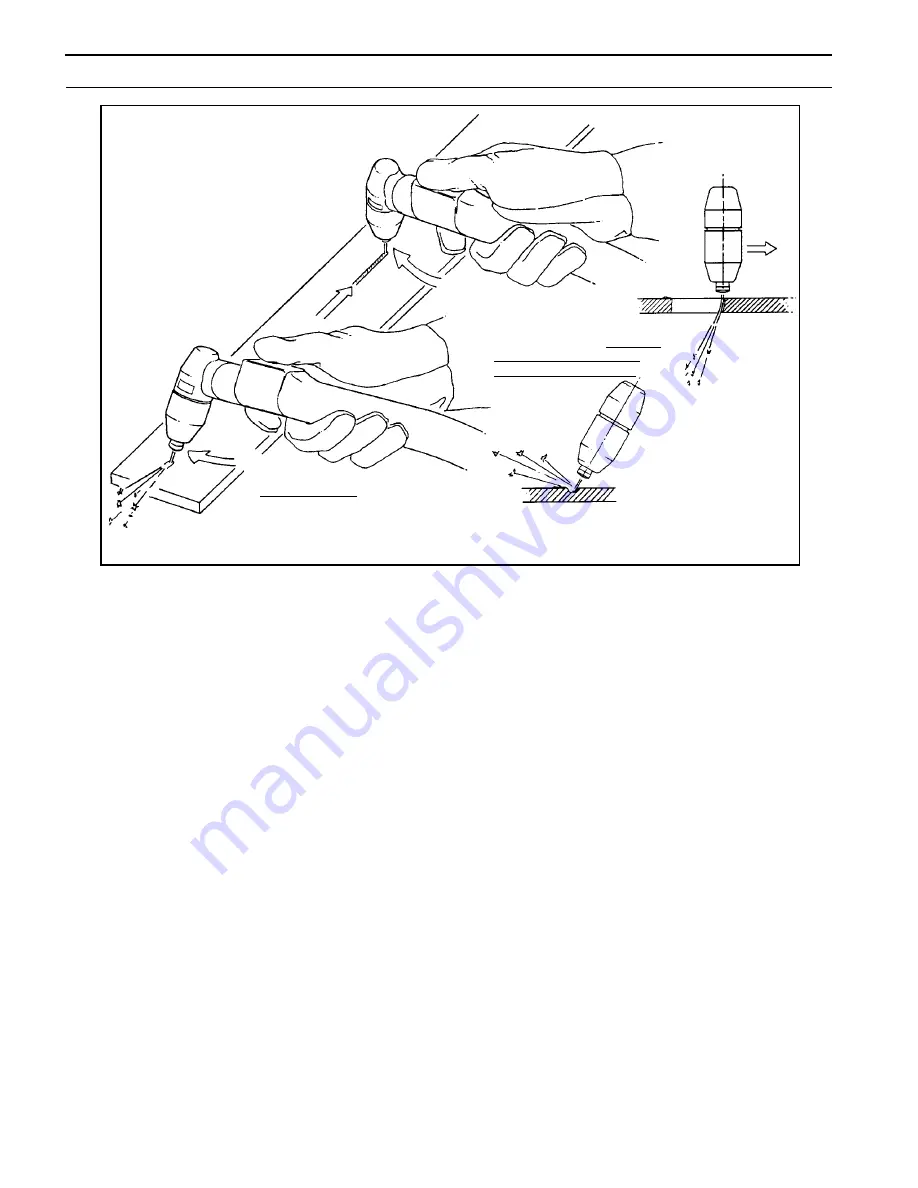

WHEN THE ARC BREAKS

THROUGH THE WORK, BRING THE

TORCH TO AN UPRIGHT POSI-

TION AND PROCEED TO CUT.

TO START A PIERCE, TILT THE TORCH

TO PREVENT MOLTEN MATERIAL FROM

COMING BACK AGAINST AND DAMAG-

ING THE TORCH.

1

2

CAUTION:

Locate the console at least 10-ft. from the cut-

ting work area. Chips and hot slag from the

cutting operation can damage the console.

After placing the primary (wall) switch to the ON position and

making control and air pressure adjustments as described

above, proceed as follows:

1. Touch the tip of the torch to the workpiece holding the

torch at about 15- 30

°

angle to avoid damaging the tip.

2. Depress the torch switch. (Air and high frequency should

energize.)

3. Two seconds after depressing torch switch, the plasma

arc will start cutting.

4. After starting the cut, bring the torch to an upright

position and proceed to cut by dragging the torch

along the workpiece. It may be necessary to cut with

a tip-to-work (standoff) distance of up to 1/16" due to

various material surface conditions.

Figure 3-4 Piercing Technique using the PT-31xl

5. When ending a cut, the torch switch should be released

to minimize double-arcing which can damage the tip. This

is to prevent high frequency from reigniting after cutting

arc extinguishes.

6. In the postflow mode, the arc can be restarted immediately

by depressing the torch switch. The two second preflow

will automatically cancel.

Summary of Contents for 380

Page 4: ... TABLE OF CONTENTS ...

Page 14: ...14 SECTION 1 DESCRIPTION ...

Page 26: ...26 SECTION 3 OPERATION ...

Page 30: ...30 SECTION 4 MAINTENANCE WORK LEAD CONNECTION TORCH CONNECTION ...

Page 41: ...41 Notes ...

Page 42: ...Notes ...

Page 43: ...Revision History Original release 06 2006 03 2007 Revised Title Page layout text ...